Table of Contents

Benefits of Using API Seamless Pipe in Oilfield Operations

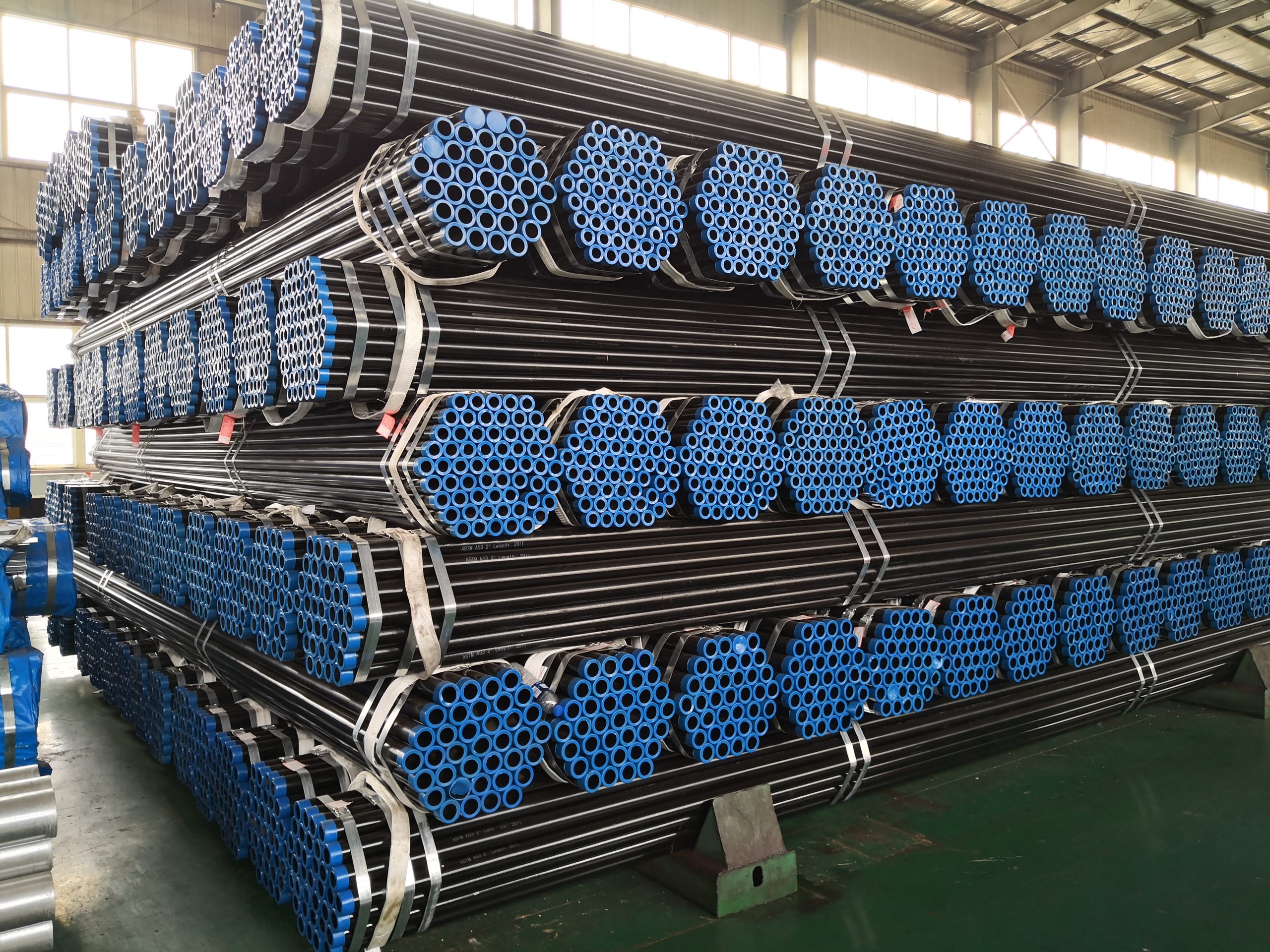

API seamless pipe OCTG casing tubing plays a crucial role in oilfield operations, providing a reliable and efficient solution for Transporting oil and gas from the well to the surface. These pipes are designed to withstand high pressure and extreme temperatures, making them ideal for use in the harsh conditions of the oilfield.

One of the key benefits of using API seamless pipe in oilfield operations is its durability. These pipes are made from high-quality materials that are able to withstand the rigors of the oilfield Environment, including corrosion, abrasion, and high pressure. This durability ensures that the pipes will last for a long time, reducing the need for frequent replacements and maintenance.

In addition to their durability, API seamless pipes are also known for their high performance. These pipes are designed to provide a smooth and efficient flow of oil and gas, minimizing the risk of blockages and ensuring that the production process runs smoothly. This high performance is essential for maximizing the productivity of oilfield operations and ensuring that the oil and gas can be extracted efficiently.

Another benefit of using API seamless pipe in oilfield operations is its versatility. These pipes can be used in a wide range of applications, from drilling and production to transportation and storage. This versatility makes API seamless pipes a cost-effective solution for oilfield operators, as they can be used in multiple stages of the production process without the need for additional equipment or materials.

Furthermore, API seamless pipes are also known for their reliability. These pipes are manufactured to strict quality standards set by the American Petroleum Institute (API), ensuring that they meet the highest industry standards for performance and Safety. This reliability gives oilfield operators peace of mind, knowing that they can rely on API seamless pipes to deliver consistent and dependable performance in even the most challenging conditions.

In conclusion, API seamless pipe OCTG casing tubing offers a range of benefits for oilfield operations, including durability, high performance, versatility, and reliability. These pipes are an essential component of the oil and gas industry, providing a reliable and efficient solution for transporting oil and gas from the well to the surface. By using API seamless pipes, oilfield operators can maximize the productivity of their operations and ensure the safe and efficient extraction of oil and gas.

How to Choose the Right OCTG Casing and Tubing for Oilfield Service

API seamless pipe OCTG casing tubing plays a crucial role in the oilfield service industry. These pipes are used for various applications, including drilling, production, and transportation of oil and gas. Choosing the right OCTG casing and tubing is essential to ensure the success and efficiency of oilfield operations.

When selecting OCTG casing and tubing, there are several factors to consider. One of the most important considerations is the material of the pipe. API seamless pipes are made from high-quality materials that are designed to withstand the harsh conditions of the oilfield. These pipes are manufactured according to the American Petroleum Institute (API) standards, which ensure their quality and reliability.

In addition to the material, the size and weight of the OCTG casing and tubing are also important factors to consider. The size of the pipe will depend on the specific requirements of the oilfield operation, such as the depth of the well and the pressure of the reservoir. The weight of the pipe is also crucial, as it will determine the strength and durability of the pipe under high-pressure conditions.

Another important consideration when choosing OCTG casing and tubing is the type of connection used. API seamless pipes are available with various types of connections, such as threaded, coupled, or integral connections. The type of connection will depend on the specific requirements of the oilfield operation and the type of equipment used in the drilling and production process.

It is also essential to consider the corrosion resistance of the OCTG casing and tubing. Oilfield operations are often conducted in harsh environments that can cause corrosion and degradation of the pipes over time. API seamless pipes are designed to resist corrosion and maintain their integrity even in challenging conditions.

Furthermore, the performance of the OCTG casing and tubing is another crucial factor to consider. API seamless pipes are known for their high performance and reliability, making them ideal for oilfield service applications. These pipes are designed to provide excellent mechanical properties, such as high tensile strength and impact resistance, to ensure the success of oilfield operations.

In conclusion, choosing the right OCTG casing and tubing is essential for the success and efficiency of oilfield service operations. API seamless pipes are a reliable and high-quality option for oilfield applications, offering excellent performance, corrosion resistance, and durability. By considering factors such as material, size, weight, connection type, and corrosion resistance, oilfield operators can select the best OCTG casing and tubing for their specific needs. With the right choice of OCTG casing and tubing, oilfield operations can be conducted safely and efficiently, ensuring the success of the project.