Table of Contents

Benefits of Using Wire Cable Wrap for Cable Management

Wire cable wrap, also known as IWRC steel wire Rope, is a versatile and durable solution for cable management in a variety of industries. This type of cable wrap is made from high-strength steel wire that is tightly wound around a central core, providing excellent strength and flexibility for securing and organizing cables. In this article, we will explore the benefits of using wire cable wrap for cable management.

One of the key advantages of wire cable wrap is its superior strength and durability. The high-strength steel wire used in this type of cable wrap is capable of withstanding heavy loads and harsh environmental conditions, making it ideal for use in industrial settings where cables are subjected to frequent movement and wear. Additionally, the tightly wound construction of wire cable wrap helps to prevent kinks and tangles in cables, ensuring smooth and reliable operation.

Another benefit of wire cable wrap is its flexibility and ease of installation. Unlike rigid cable management solutions, such as conduit or raceway, wire cable wrap can be easily bent and shaped to fit around corners and Obstacles, making it ideal for use in tight spaces where traditional cable management methods may be impractical. Additionally, the lightweight construction of wire cable wrap makes it easy to handle and install, reducing the time and effort required for cable management tasks.

In addition to its strength and flexibility, wire cable wrap also offers excellent protection for cables against abrasion, corrosion, and other forms of damage. The steel wire construction of wire cable wrap provides a durable barrier that helps to shield cables from external hazards, such as sharp edges, rough surfaces, and exposure to moisture or Chemicals. This added layer of protection can help to extend the lifespan of cables and reduce the risk of costly downtime due to cable failure.

Furthermore, wire cable wrap is a cost-effective solution for cable management, offering a durable and long-lasting alternative to more expensive cable management options. The high-strength steel wire used in wire cable wrap is resistant to wear and tear, reducing the need for frequent replacements and maintenance. Additionally, the flexibility and ease of installation of wire cable wrap can help to lower labor costs and minimize downtime during cable management projects.

Overall, wire cable wrap is a versatile and reliable solution for cable management that offers a range of benefits, including superior strength and durability, flexibility and ease of installation, excellent protection for cables, and cost-effectiveness. Whether used in industrial settings, commercial buildings, or residential applications, wire cable wrap provides a durable and efficient way to secure and organize cables for optimal performance and reliability.

Understanding the Importance of IWRC Steel Wire Rope in Industrial Applications

Wire cable wrap, also known as IWRC steel wire rope, is a crucial component in various industrial applications. Its strength, durability, and flexibility make it an essential tool for lifting, towing, and securing heavy loads. Understanding the importance of IWRC steel wire rope in industrial settings is key to ensuring the Safety and efficiency of operations.

One of the primary reasons IWRC steel wire rope is preferred in industrial applications is its high tensile strength. This type of wire rope is constructed with a core made of independent wire rope strands, which provides added strength and stability. This core, known as the independent wire rope core (IWRC), enhances the overall strength of the wire rope, making it ideal for lifting heavy loads in industrial settings.

In addition to its strength, IWRC steel wire rope is also known for its durability. Industrial environments can be harsh and demanding, with exposure to extreme temperatures, chemicals, and heavy loads. IWRC steel wire rope is designed to withstand these challenging conditions, ensuring that it can perform reliably and safely in a variety of industrial applications.

The flexibility of IWRC steel wire rope is another key factor that makes it a popular choice in industrial settings. Its ability to bend and flex without compromising its strength or integrity allows for smooth and efficient operation in lifting and towing applications. This flexibility also makes it easier to handle and maneuver, reducing the risk of accidents and injuries in the workplace.

When it comes to safety, IWRC steel wire rope is a top choice for industrial applications. Its high tensile strength, durability, and flexibility all contribute to its overall safety performance. Proper installation, maintenance, and inspection of IWRC steel wire rope are essential to ensuring its safe and effective use in industrial settings. Regular inspections can help identify any signs of wear or damage, allowing for timely repairs or replacements to prevent accidents and injuries.

In conclusion, IWRC steel wire rope plays a vital role in industrial applications due to its strength, durability, flexibility, and safety features. Understanding the importance of IWRC steel wire rope in industrial settings is crucial for ensuring the efficiency and safety of operations. By choosing the right type of wire rope for specific applications, conducting regular inspections, and following proper installation and maintenance procedures, industrial operators can maximize the performance and longevity of IWRC steel wire rope in their operations.

Comparison of Different Types of Wire Cable Wrap for Various Uses

Wire cable wrap, also known as wire rope, is a versatile tool used in a variety of industries for lifting, towing, and securing heavy loads. There are several different types of wire cable wrap available, each with its own unique characteristics and advantages. In this article, we will compare two popular types of wire cable wrap: IWRC steel wire rope and Fiber core wire rope.

IWRC steel wire rope, or Independent Wire Rope Core, is a type of wire cable wrap that features a separate wire strand at the core of the rope. This core provides added strength and stability to the rope, making it ideal for heavy-duty applications where durability is essential. IWRC steel wire rope is commonly used in construction, mining, and oil and gas industries, where it is subjected to high Levels of stress and tension.

One of the key advantages of IWRC steel wire rope is its superior strength and resistance to abrasion. The independent wire core helps distribute the load evenly across the rope, reducing the risk of breakage or failure. This makes IWRC steel wire rope a reliable choice for lifting and hoisting heavy loads in demanding environments.

In addition to its strength, IWRC steel wire rope is also highly resistant to corrosion and rust, making it suitable for outdoor use in harsh weather conditions. This durability ensures that the rope will maintain its integrity over time, reducing the need for frequent replacements and maintenance.

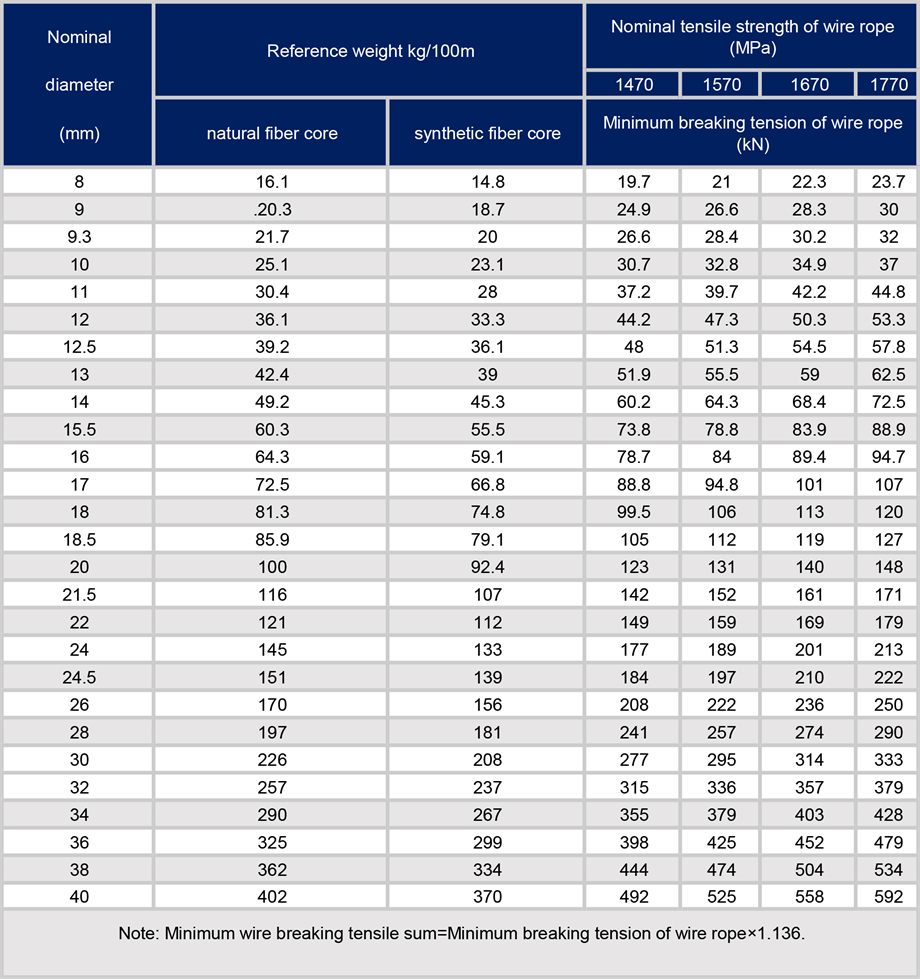

On the other hand, fiber core wire rope is a type of wire cable wrap that features a core made of synthetic fibers, such as polypropylene or nylon. This type of wire rope is lighter and more flexible than IWRC steel wire rope, making it easier to handle and maneuver in tight spaces. Fiber core wire rope is commonly used in marine and Fishing industries, where flexibility and ease of use are important considerations.

While fiber core wire rope may not have the same level of strength as IWRC steel wire rope, it is still capable of handling moderate loads and is suitable for a wide range of applications. The synthetic core provides some cushioning and shock absorption, which can be beneficial when lifting delicate or fragile items.

One of the main advantages of fiber core wire rope is its resistance to crushing and flattening, which can occur when the rope is wound tightly around a Drum or pulley. The synthetic fibers in the core help maintain the shape and integrity of the rope, ensuring smooth operation and prolonging the lifespan of the rope.

In conclusion, both IWRC steel wire rope and fiber core wire rope have their own unique advantages and applications. IWRC steel wire rope is best suited for heavy-duty lifting and towing tasks where strength and durability are paramount, while fiber core wire rope is more suitable for lighter loads and applications where flexibility and ease of handling are important. Ultimately, the choice between the two types of wire cable wrap will depend on the specific requirements of the job at hand.