Table of Contents

What Does the Core of a Wire Rope Do?

Wire ropes are essential components in various industries, including construction, mining, and transportation. They are used for lifting heavy loads, securing structures, and providing support in various applications. One crucial element of a wire rope is its core, which plays a significant role in the overall performance and durability of the rope.

The core of a wire rope is the central part that provides support and stability to the outer strands. It is typically made of either Fiber or steel, depending on the specific requirements of the application. The core serves as a foundation for the strands, helping to distribute the load evenly and prevent the rope from deforming or breaking under stress.

In wire ropes with a fiber core, the core is usually made of natural or synthetic fibers such as sisal, polypropylene, or nylon. These materials are lightweight, flexible, and resistant to moisture, making them ideal for applications where weight and environmental conditions are a concern. Fiber cores provide cushioning and shock absorption, reducing wear and tear on the outer strands and prolonging the life of the rope.

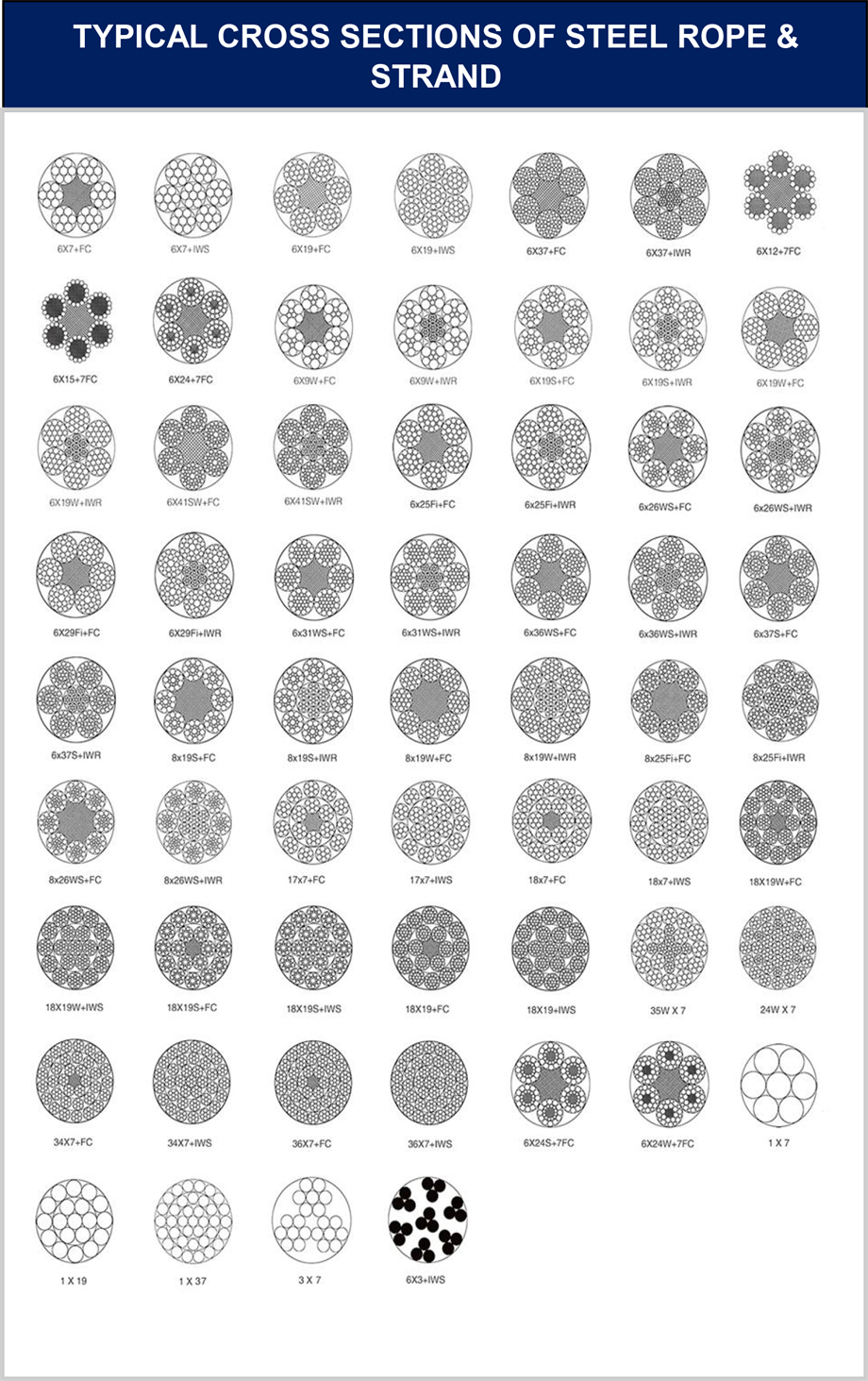

On the other hand, wire ropes with a steel core are more robust and durable, making them suitable for heavy-duty applications that require high strength and resistance to abrasion. Steel cores are typically made of either independent wire rope core (IWRC) or wire strand core (WSC). IWRC cores consist of a separate strand of steel wires laid in the center of the rope, while WSC cores are made of the same wires that form the outer strands.

The core of a wire rope also affects its flexibility and bending characteristics. Ropes with a fiber core are more flexible and easier to handle, making them suitable for applications that require frequent bending and coiling. In contrast, ropes with a steel core are stiffer and less flexible, but they offer higher tensile strength and better resistance to crushing and deformation.

To ensure the optimal performance and longevity of a wire rope, proper maintenance and lubrication are essential. Stainless Steel wire eye straps are commonly used to secure wire ropes to various structures and equipment. These eye straps are made of high-quality stainless steel, which is corrosion-resistant and durable, ensuring a secure and reliable connection.

Wire rope lubricant is another crucial component in maintaining the performance of a wire rope. Lubricants help reduce friction between the strands, preventing wear and extending the life of the rope. They also protect against corrosion and rust, especially in outdoor or marine environments where exposure to moisture and Salt can accelerate degradation.

In conclusion, the core of a wire rope plays a vital role in its overall performance and durability. Whether made of fiber or steel, the core provides support, stability, and strength to the outer strands, ensuring the safe and efficient operation of the rope. Proper maintenance, including the use of stainless steel wire eye straps and wire rope lubricant, is essential to maximize the lifespan and reliability of wire ropes in various applications.

Stainless Steel Wire Eye Straps

Wire rope is a crucial component in various industries, including construction, mining, and marine applications. It is made up of multiple strands of metal wire twisted together to form a strong and flexible cable. At the core of a wire rope lies a central component that provides stability and strength to the entire structure.

The core of a wire rope serves as the foundation on which the outer strands are laid. It provides support and helps distribute the load evenly across the entire length of the rope. Without a solid core, the wire rope would be prone to kinking, crushing, and deformation under heavy loads. The core also helps maintain the shape and integrity of the rope, ensuring its longevity and durability.

Stainless steel wire eye straps are commonly used in conjunction with wire ropes to create secure anchor points for lifting and rigging applications. These eye straps are made from high-quality stainless steel, which offers excellent corrosion resistance and strength. They are designed to be attached to a surface or structure using Screws or Bolts, providing a reliable anchor point for attaching Hooks, Shackles, or Other Hardware.

Stainless steel wire eye straps come in various sizes and configurations to accommodate different wire rope diameters and load capacities. They are typically used in conjunction with Thimbles to prevent the wire rope from being crushed or damaged at the attachment point. By using stainless steel wire eye straps, operators can ensure that their wire rope assemblies are secure and reliable, even under heavy loads.

In order to maintain the performance and longevity of wire ropes, proper lubrication is essential. Wire rope lubricant is specifically designed to penetrate the strands of the wire rope, reducing friction and wear during operation. It also helps protect the wire rope from corrosion and rust, extending its service life and reducing maintenance costs.

Wire rope lubricant is typically applied using a spray or brush, ensuring that all strands are adequately coated. Regular lubrication of wire ropes is essential to prevent premature wear and failure, especially in high-load or high-speed applications. By using a high-quality wire rope lubricant, operators can ensure that their wire ropes operate smoothly and efficiently, reducing downtime and maintenance costs.

In conclusion, the core of a wire rope plays a crucial role in providing stability and strength to the entire structure. Stainless steel wire eye straps are commonly used to create secure anchor points for wire ropes, ensuring reliable and safe lifting and rigging operations. Proper lubrication with wire rope lubricant is essential to maintain the performance and longevity of wire ropes, reducing wear and extending service life. By understanding the importance of these components and implementing proper maintenance practices, operators can ensure the safe and efficient operation of their wire rope assemblies.

Wire Rope Lubricant

Wire rope lubricant is a crucial component in maintaining the longevity and performance of wire ropes. These ropes are commonly used in various industries such as construction, mining, and marine applications due to their strength and durability. However, without proper lubrication, wire ropes can suffer from premature wear and corrosion, leading to potential Safety hazards and costly repairs.

The core of a wire rope plays a vital role in its overall strength and flexibility. The core is the central part of the rope around which the strands are twisted. It provides support and stability to the outer strands, allowing the rope to maintain its shape and strength under heavy loads. Without a strong and well-maintained core, the wire rope may become prone to kinking, crushing, and other forms of damage.

Stainless steel wire eye straps are commonly used in conjunction with wire ropes to create secure anchor points for lifting and rigging applications. These eye straps are designed to be attached to a surface or structure, providing a reliable connection point for the wire rope. Stainless steel is chosen for its corrosion resistance and durability, making it ideal for use in harsh environments where exposure to moisture and Chemicals is common.

When it comes to maintaining wire ropes and ensuring their optimal performance, proper lubrication is key. Wire rope lubricant is specifically formulated to penetrate the strands of the rope, reducing friction and wear during operation. This helps to extend the lifespan of the wire rope and improve its overall efficiency.

There are several types of wire rope lubricants available on the market, each with its own unique properties and benefits. Some lubricants are designed for specific applications, such as high-temperature environments or marine settings. It is important to choose the right lubricant for your particular needs to ensure maximum effectiveness.

Applying wire rope lubricant is a relatively simple process that can be done by hand or with the help of a lubrication system. The lubricant should be evenly distributed along the length of the wire rope, ensuring that all strands are adequately coated. Regular lubrication is recommended to prevent dryness and corrosion, especially in environments where the wire rope is exposed to moisture or harsh chemicals.

In conclusion, the core of a wire rope plays a crucial role in its overall strength and flexibility, while stainless steel wire eye straps provide secure anchor points for lifting and rigging applications. Proper lubrication is essential for maintaining wire ropes and ensuring their optimal performance. By choosing the right lubricant and applying it regularly, you can extend the lifespan of your wire ropes and reduce the risk of premature wear and damage. Remember to always follow the manufacturer’s recommendations for lubrication and maintenance to keep your wire ropes in top condition.