Table of Contents

Sustainable Practices in Basalt Chopped Fiber Yarn Production

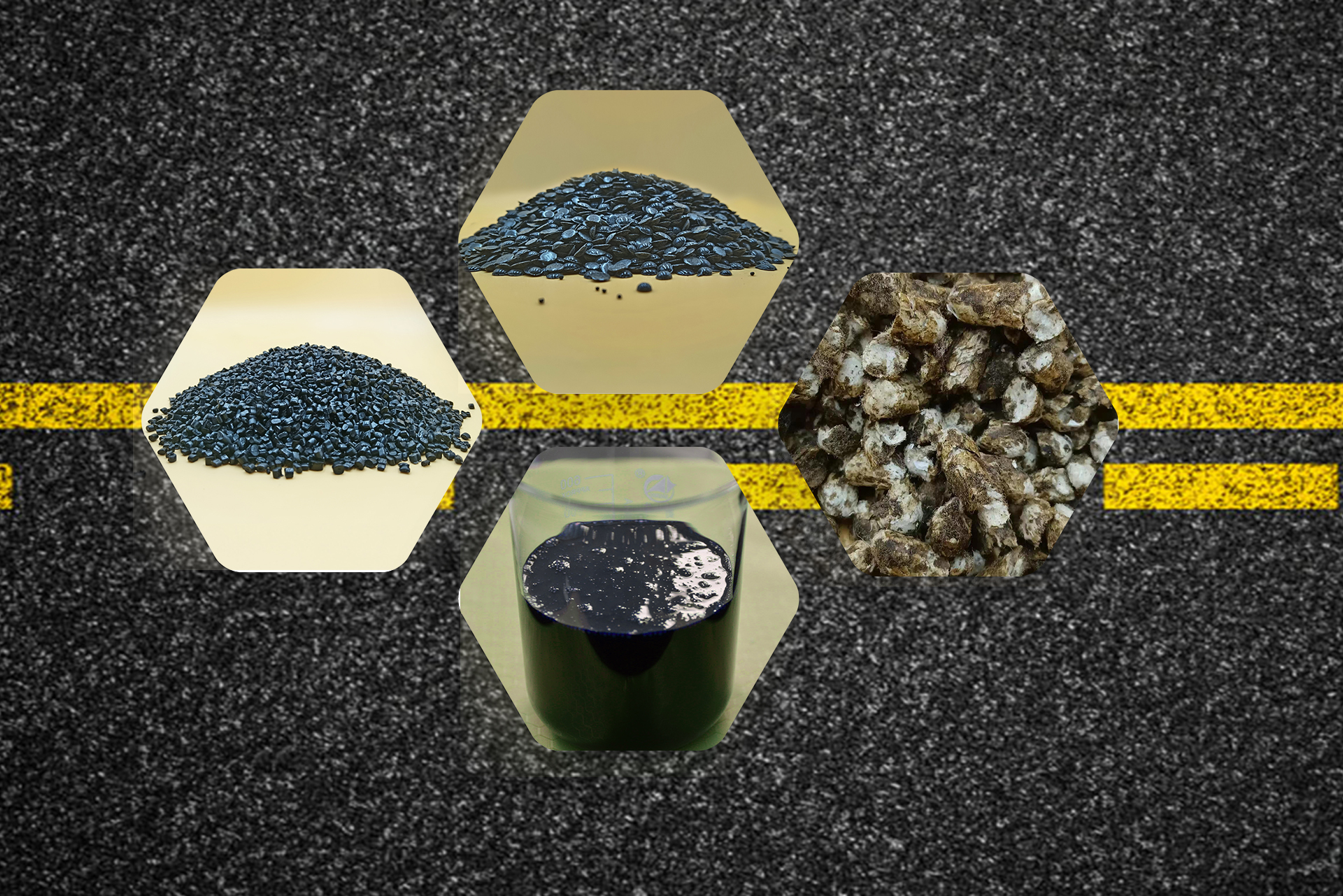

Basalt chopped fiber yarn is a sustainable alternative to traditional materials like fiberglass and carbon fiber. It is made from basalt rock, which is a naturally occurring volcanic rock that is abundant in many parts of the world. The production process of basalt chopped fiber yarn has a lower environmental impact compared to other materials, making it a popular choice for industries looking to reduce their carbon footprint.

One of the key benefits of using basalt chopped fiber yarn is its low energy consumption during production. The process of turning basalt rock into fiber yarn requires less energy compared to the production of fiberglass or carbon fiber. This is because basalt rock has a lower melting point, which means it can be processed at lower temperatures, reducing the overall energy consumption of the production process.

In addition to its low energy consumption, basalt chopped fiber yarn also has a lower carbon footprint compared to other materials. Basalt rock is a naturally occurring material that does not require any additional Chemicals or additives to be processed into fiber yarn. This means that the production of basalt chopped fiber yarn generates fewer greenhouse gas emissions compared to the production of fiberglass or carbon fiber.

Furthermore, basalt chopped fiber yarn is a recyclable material, which means that it can be reused or repurposed at the end of its life cycle. This is in stark contrast to materials like fiberglass, which are difficult to recycle and often end up in landfills. By choosing basalt chopped fiber yarn, industries can reduce their environmental impact and contribute to a more sustainable future.

| Number | Name |

| 1 | basalt Chopped Fiber |

Another environmental benefit of using basalt chopped fiber yarn is its durability and longevity. Basalt rock is a naturally strong material that is resistant to corrosion and degradation. This means that products made from basalt chopped fiber yarn have a longer lifespan compared to products made from other materials. This not only reduces the amount of waste generated but also decreases the need for frequent replacements, further reducing the environmental impact of production and use.

Overall, the environmental impact of producing and using basalt chopped fiber yarn is significantly lower compared to traditional materials like fiberglass and carbon fiber. Its low energy consumption, recyclability, durability, and longevity make it a sustainable choice for industries looking to reduce their carbon footprint and contribute to a more environmentally friendly future.

In conclusion, basalt chopped fiber yarn is a sustainable alternative to traditional materials that offers numerous environmental benefits. Its low energy consumption, recyclability, durability, and longevity make it an attractive choice for industries looking to reduce their environmental impact. By choosing basalt chopped fiber yarn, industries can contribute to a more sustainable future and help protect the planet for future generations.

Advantages of Using Basalt Chopped Fiber Yarn for Eco-Friendly Products

Basalt chopped fiber yarn is a sustainable and eco-friendly material that is gaining popularity in various industries due to its numerous advantages. This material is made from basalt rock, which is a natural volcanic rock that is abundant in the earth’s crust. The process of producing basalt chopped fiber yarn involves melting the basalt rock at high temperatures and then extruding it into fibers. These fibers are then chopped into yarns of various lengths, which can be used in a wide range of applications.

One of the key advantages of using basalt chopped fiber yarn is its environmental impact. Unlike traditional materials such as fiberglass, which are made from non-renewable resources like petroleum, basalt chopped fiber yarn is made from a natural and abundant resource. This means that the production of basalt chopped fiber yarn has a lower carbon footprint compared to other materials, making it a more sustainable choice for eco-friendly products.

In addition to being made from a renewable resource, basalt chopped fiber yarn is also recyclable and biodegradable. This means that at the end of its life cycle, the material can be recycled and used to create new products, reducing the amount of waste that ends up in landfills. This makes basalt chopped fiber yarn a more environmentally friendly option compared to materials that are not recyclable or biodegradable.

Furthermore, the production of basalt chopped fiber yarn requires less energy compared to other materials like fiberglass. This is because basalt rock has a lower melting point than glass, which means that less energy is needed to melt the rock and extrude it into fibers. This results in lower greenhouse gas emissions and energy consumption during the production process, making basalt chopped fiber yarn a more sustainable choice for environmentally conscious consumers.

Another advantage of using basalt chopped fiber yarn is its durability and strength. Basalt rock is known for its high tensile strength and resistance to heat and chemicals, making basalt chopped fiber yarn an ideal material for applications that require high performance and durability. This material is commonly used in industries such as automotive, aerospace, construction, and marine, where strength and durability are essential.

In conclusion, basalt chopped fiber yarn is a sustainable and eco-friendly material that offers numerous advantages over traditional materials like fiberglass. Its lower environmental impact, recyclability, and durability make it an attractive choice for eco-friendly products in various industries. By choosing basalt chopped fiber yarn, manufacturers can reduce their carbon footprint and contribute to a more sustainable future for our planet.