Table of Contents

Steel Wire Rope Weight Per Meter: Factors Affecting and Calculating Methods

Steel wire ropes are essential components in various industries, including construction, mining, and transportation. They are used for lifting heavy loads, securing structures, and providing support in various applications. One crucial aspect of steel wire ropes is their weight per meter, which plays a significant role in determining their strength and performance.

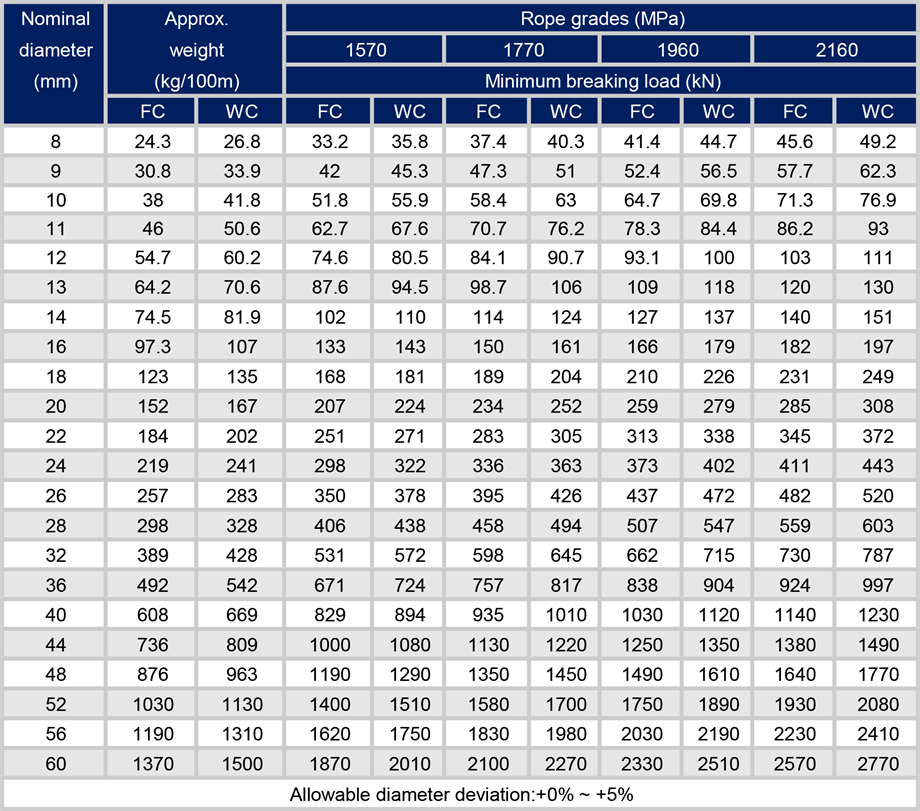

The weight per meter of a steel wire rope is influenced by several factors, including the diameter of the rope, the material used, and the construction type. Thicker ropes made of high-strength materials will generally have a higher weight per meter compared to thinner ropes made of lower-strength materials. Additionally, the construction type of the rope, such as the number of strands and wires, can also impact its weight per meter.

Calculating the weight per meter of a steel wire rope is essential for determining its load capacity and ensuring safe and efficient operation. There are several methods for calculating the weight per meter of a steel wire rope, depending on the specific characteristics of the rope. One common method is to use the formula:

Weight per meter = (D^2 x L x W) / 162.27

Where D is the diameter of the rope in millimeters, L is the length of the rope in meters, and W is the weight of the material in kilograms per cubic meter. This formula provides a simple and accurate way to calculate the weight per meter of a steel wire rope based on its diameter, length, and material density.

Another method for calculating the weight per meter of a steel wire rope is to use a steel wire rope weight calculator. These online tools allow users to input the specific characteristics of the rope, such as diameter, material, and construction type, and quickly calculate the weight per meter. This method is convenient and efficient for determining the weight per meter of a steel wire rope without the need for manual calculations.

In addition to calculating the weight per meter of a steel wire rope, it is also essential to consider the weight of the rope itself when determining its load capacity. The weight of the rope must be factored into the total load to ensure that the rope can safely support the intended weight without exceeding its capacity. This is particularly important in applications where the weight of the rope is significant compared to the load being lifted or secured.

Steel wire rope cutters are essential tools for cutting and trimming steel wire ropes to the desired length. These tools are designed to provide clean and precise cuts without damaging the integrity of the rope. Steel wire rope cutters come in various sizes and styles to accommodate different rope diameters and construction types.

When selecting a steel wire rope cutter, it is essential to consider the diameter and construction type of the rope being cut. Some cutters are specifically designed for cutting thicker ropes with multiple strands and wires, while others are more suitable for thinner ropes with fewer strands. It is crucial to choose a cutter that is compatible with the specific characteristics of the rope to ensure clean and accurate cuts.

In conclusion, the weight per meter of a steel wire rope is a critical factor in determining its strength and performance. Calculating the weight per meter of a steel wire rope is essential for ensuring safe and efficient operation in various applications. Steel wire rope cutters are essential tools for cutting and trimming steel wire ropes to the desired length, providing clean and precise cuts without compromising the integrity of the rope. By understanding the factors affecting steel wire rope weight per meter and selecting the appropriate cutter, users can ensure the safe and effective use of steel wire ropes in their applications.

How to Choose the Right Steel Wire Rope Cutter for Your Needs

Steel wire ropes are essential tools in various industries, from construction to mining to marine applications. These ropes are made up of multiple strands of steel wire twisted together to form a strong and durable cable. When it comes to cutting steel wire ropes, having the right tool for the job is crucial. In this article, we will discuss the importance of choosing the right steel wire rope cutter for your needs.

One of the key factors to consider when choosing a steel wire rope cutter is the weight of the rope per meter. The weight of the rope per meter will determine the thickness and strength of the rope, which in turn will affect the type of cutter you will need. Heavier ropes will require more powerful cutters that can handle the increased thickness and strength of the wire.

Another important factor to consider when choosing a steel wire rope cutter is the type of rope you will be cutting. Different types of steel wire ropes have different properties, such as tensile strength and flexibility. Some ropes may be more difficult to cut than others, requiring a more specialized cutter. It is important to consider the specific properties of the rope you will be working with to ensure that you choose a cutter that can handle the job effectively.

In addition to the weight and type of rope, it is also important to consider the size and design of the cutter itself. Some cutters are designed for specific sizes of wire rope, while others are more versatile and can handle a range of sizes. The design of the cutter will also affect its ease of use and efficiency. For example, some cutters may have ergonomic Handles or Safety features that make them easier and safer to use.

When choosing a steel wire rope cutter, it is important to consider the specific requirements of your job. If you will be cutting a large volume of rope on a regular basis, you may need a more heavy-duty cutter that can handle the workload. On the other hand, if you will only be cutting small amounts of rope occasionally, a lighter and more portable cutter may be sufficient.

It is also important to consider the quality and durability of the cutter. A high-quality cutter will be made of strong materials that can withstand the rigors of cutting steel wire ropes. It is important to choose a cutter from a reputable manufacturer that offers a warranty or guarantee on their products.

In conclusion, choosing the right steel wire rope cutter is essential for ensuring the efficiency and safety of your work. By considering factors such as the weight, type, size, and design of the cutter, as well as the specific requirements of your job, you can select a cutter that meets your needs effectively. Investing in a high-quality cutter from a reputable manufacturer will ensure that you have a reliable tool that can handle the demands of cutting steel wire ropes.

Comparing Different Types of Steel Wire Rope Cutters: Pros and Cons

Steel wire ropes are essential components in various industries, including construction, mining, and transportation. These ropes are used for lifting heavy loads, securing structures, and providing support in various applications. When working with steel wire ropes, it is crucial to have the right tools to cut them efficiently and safely. One of the most important factors to consider when choosing a steel wire rope cutter is its weight per meter.

The weight per meter of a steel wire rope cutter is a critical factor that determines its portability and ease of use. A lighter cutter is easier to handle and maneuver, making it ideal for tasks that require precision and control. On the other hand, a heavier cutter may offer more stability and power, but it can be cumbersome to use for extended periods.

When comparing different types of steel wire rope cutters, it is essential to consider their weight per meter to determine which one is best suited for your needs. Some cutters are designed to be lightweight and compact, making them ideal for on-the-go use. These cutters are often made of high-quality materials that are durable and long-lasting, despite their lightweight construction.

On the other hand, some steel wire rope cutters are heavier and more robust, offering increased cutting power and stability. These cutters are ideal for heavy-duty tasks that require cutting through thick and tough steel wire ropes. While these cutters may be heavier, they are designed to provide maximum cutting efficiency and precision, making them essential tools for demanding applications.

When choosing a steel wire rope cutter, it is essential to consider the weight per meter of the tool to ensure that it meets your specific requirements. Lightweight cutters are ideal for tasks that require agility and precision, while heavier cutters are better suited for heavy-duty applications that demand power and stability. By understanding the pros and cons of each type of cutter, you can make an informed decision that will help you complete your tasks efficiently and safely.

In addition to considering the weight per meter of a steel wire rope cutter, it is also essential to evaluate other factors such as cutting capacity, blade quality, and safety features. Some cutters are equipped with advanced features such as ergonomic handles, safety Locks, and adjustable cutting angles, making them versatile and user-friendly. These features can enhance the overall performance of the cutter and ensure that you can work safely and efficiently.

Ultimately, the choice of a steel wire rope cutter depends on your specific needs and preferences. Whether you prioritize portability, cutting power, or safety features, there is a wide range of cutters available on the market to suit your requirements. By comparing different types of cutters and considering their weight per meter, you can select the best tool for your tasks and achieve optimal results in your work.