Table of Contents

Benefits of Using Stainless Steel Wire Mesh in Industrial Applications

Stainless Steel Wire Mesh is a versatile and durable material that is commonly used in a wide range of industrial applications. Its unique properties make it an ideal choice for various industries, including construction, Agriculture, mining, and manufacturing. One of the key benefits of using stainless steel wire mesh is its strength and durability. Stainless steel is known for its high tensile strength, which makes it resistant to corrosion, rust, and wear and tear. This makes it an excellent choice for applications where the material will be exposed to harsh conditions or high temperatures.

Another advantage of stainless steel wire mesh is its versatility. It can be easily customized to meet specific requirements, such as size, shape, and mesh density. This flexibility makes it suitable for a wide range of applications, from filtering and screening to fencing and reinforcement. In addition, stainless steel wire mesh is easy to install and maintain, making it a cost-effective solution for many industrial applications.

One of the key benefits of using stainless steel wire mesh is its resistance to corrosion. Stainless steel is a non-reactive material that does not rust or corrode when exposed to moisture, Chemicals, or extreme temperatures. This makes it an ideal choice for applications where the material will be in contact with water, acids, or other corrosive substances. In addition, stainless steel wire mesh is easy to clean and sanitize, making it suitable for use in food processing, pharmaceutical, and medical applications.

Stainless steel wire mesh is also known for its high temperature resistance. It can withstand extreme heat without losing its strength or shape, making it suitable for applications where the material will be exposed to high temperatures or fire. This makes it an ideal choice for industrial ovens, furnaces, and other high-temperature applications.

In addition to its strength, durability, and resistance to corrosion and high temperatures, stainless steel wire mesh is also a sustainable and environmentally friendly material. Stainless steel is 100% recyclable and can be reused indefinitely without losing its properties. This makes it a sustainable choice for industries that are looking to reduce their environmental impact and carbon footprint.

Overall, stainless steel wire mesh offers a wide range of benefits for industrial applications. Its strength, durability, versatility, resistance to corrosion and high temperatures, and sustainability make it an ideal choice for a wide range of industries. Whether you need a material for filtering, screening, fencing, or reinforcement, stainless steel wire mesh is a reliable and cost-effective solution that will meet your specific requirements.

How to Customize Wire Rope for Specific Projects

Wire rope is a versatile and essential component in many industries, from construction to transportation to marine applications. It is commonly used for lifting, towing, and securing heavy loads due to its strength and durability. However, not all wire rope is created equal, and sometimes standard options may not meet the specific requirements of a project. This is where customizable wire rope comes into play.

One of the most popular materials for wire rope is stainless steel. Stainless steel wire rope is known for its corrosion resistance, strength, and longevity, making it ideal for outdoor and marine applications. However, even within the realm of stainless steel wire rope, there are various options to choose from, depending on the specific needs of a project.

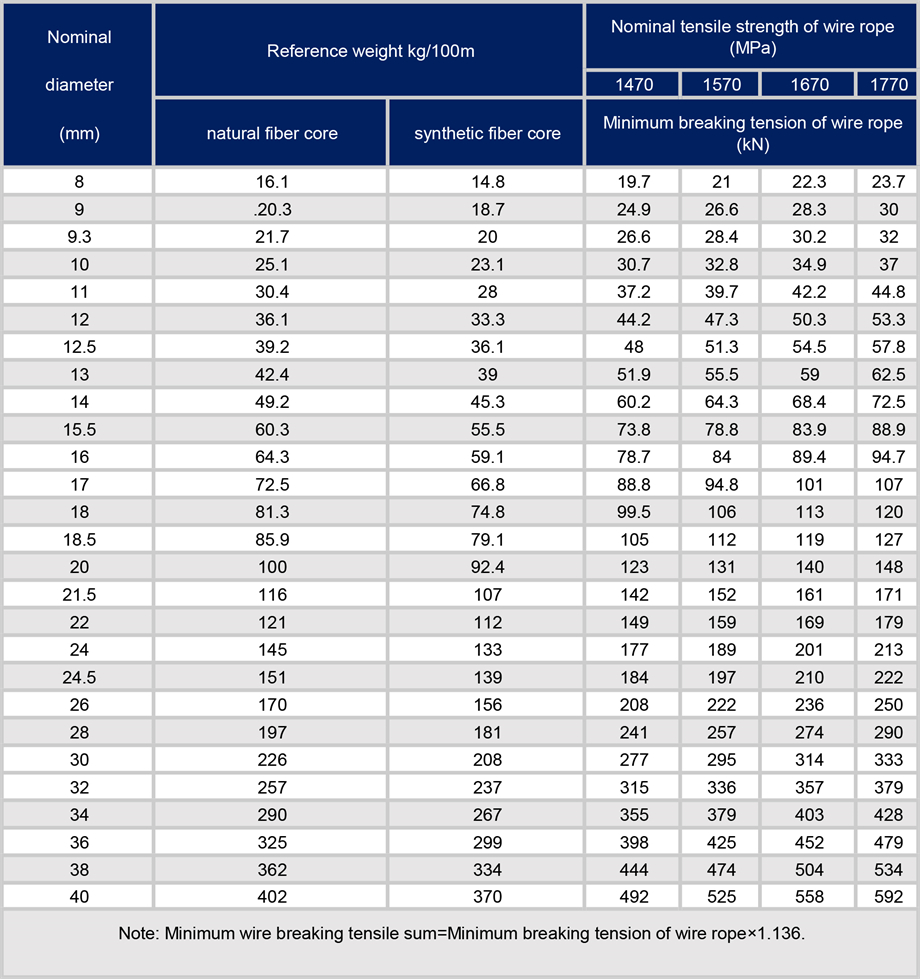

When it comes to customizing wire rope, there are several factors to consider. The first step is to determine the diameter and construction of the wire rope. The diameter of the wire rope will affect its strength and flexibility, so it is important to choose the right size for the job. The construction of the wire rope refers to the arrangement of the individual wires that make up the rope. Different constructions offer different Levels of strength and flexibility, so it is important to select the right one for the specific application.

Another important factor to consider when customizing wire rope is the type of core. The core of the wire rope provides support and stability to the outer strands, and there are several options to choose from, including Fiber core, independent wire rope core, and wire strand core. The type of core will affect the flexibility and strength of the wire rope, so it is important to select the right one for the job.

In addition to the diameter, construction, and core of the wire rope, there are also various coatings and finishes that can be applied to customize the wire rope for specific projects. Coatings such as nylon or PVC can provide additional protection against abrasion and corrosion, while finishes such as bright or galvanized can enhance the appearance of the wire rope.

Customizable wire rope is not limited to just stainless steel. There are also options for wire rope made from materials such as galvanized steel, Carbon Steel, and Aluminum. Each material has its own unique properties and advantages, so it is important to choose the right one for the specific requirements of a project.

In conclusion, customizable wire rope is a valuable tool for meeting the specific needs of a project. By considering factors such as diameter, construction, core, coatings, and finishes, it is possible to create a wire rope that is tailored to the requirements of the job at hand. Whether it is for lifting heavy loads, securing equipment, or any other application, customizable wire rope offers a versatile and reliable solution for a wide range of industries.