Table of Contents

Benefits of Using Spiral Submerged Arc Welding (SSAW) Steel Pipe for Gas and Oil Applications

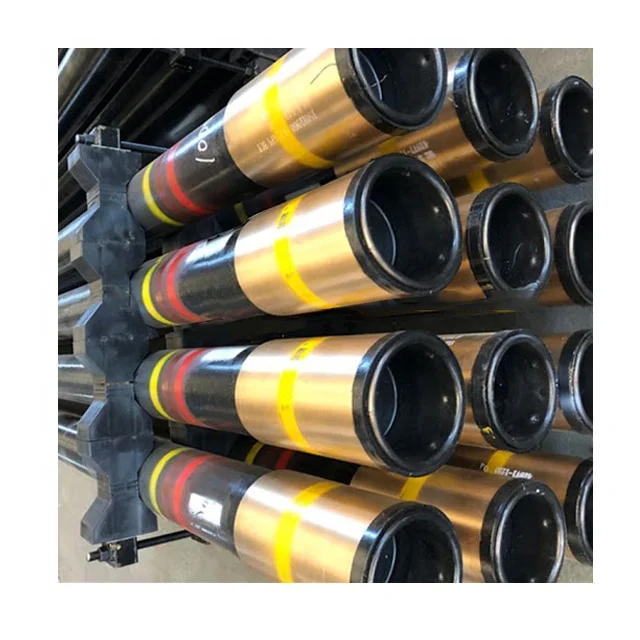

Spiral submerged arc welding (SSAW) Steel Pipes are widely used in the oil and gas industry due to their numerous benefits. These pipes are manufactured using a spiral welding process, where the steel strip is rolled into a spiral shape and welded along the seam. This results in a strong and durable pipe that is ideal for Transporting gas and oil over long distances.

One of the main benefits of using SSAW steel pipes for gas and oil applications is their high strength and durability. The spiral welding process creates a pipe with a uniform wall thickness, which helps to distribute the pressure evenly along the length of the pipe. This makes SSAW pipes less prone to leaks and failures, ensuring a reliable and efficient transportation system for gas and oil.

In addition to their strength, SSAW steel pipes are also highly resistant to corrosion. The welding process used to manufacture these pipes creates a seamless and continuous weld along the length of the pipe, which helps to prevent the formation of weak spots that are susceptible to corrosion. This makes SSAW pipes an ideal choice for transporting corrosive substances such as oil and gas, as they can withstand the harsh conditions of the Environment without deteriorating over time.

Another benefit of using SSAW steel pipes for gas and oil applications is their versatility. These pipes can be manufactured in a wide range of sizes and diameters, making them suitable for a variety of different applications. Whether you need to transport a small amount of gas or a large volume of oil, SSAW pipes can be customized to meet your specific requirements. This flexibility makes them a cost-effective and efficient solution for companies in the oil and gas industry.

Furthermore, SSAW steel pipes are easy to install and maintain, which helps to reduce downtime and increase productivity. The spiral welding process used to manufacture these pipes results in a smooth and seamless surface, which makes them easy to connect and install in the field. Additionally, the high strength and durability of SSAW pipes mean that they require minimal maintenance over their lifespan, saving companies time and money in the long run.

Overall, the benefits of using SSAW steel pipes for gas and oil applications are clear. From their high strength and durability to their resistance to corrosion and versatility, these pipes offer a reliable and efficient solution for transporting gas and oil over long distances. With their ease of installation and low maintenance requirements, SSAW pipes are a cost-effective choice for companies in the oil and gas industry looking to improve their transportation systems.

https://www.youtube.com/watch?v=q2IbtWO5RVw