Table of Contents

Benefits of Using Odex 90 Eccentric Reamer Casing System

The Odex 90 Eccentric Reamer Casing System is a revolutionary tool that has been designed to streamline the process of casing drilling. This innovative system offers a wide range of benefits that make it a preferred choice for many drilling operations. In this article, we will explore some of the key advantages of using the Odex 90 Eccentric Reamer Casing System.

One of the primary benefits of the Odex 90 Eccentric Reamer Casing System is its ability to reduce drilling time. Traditional casing drilling methods can be time-consuming and labor-intensive, requiring multiple trips in and out of the hole to set and Cement casing. With the Odex 90 system, casing can be drilled and set in a single operation, significantly reducing the time and effort required to complete the drilling process.

In addition to saving time, the Odex 90 Eccentric Reamer Casing System also offers improved hole stability. The eccentric reamer design of the system helps to create a more uniform hole, reducing the risk of hole collapse or deviation. This increased stability not only makes the drilling process safer but also helps to ensure that the casing is properly set and cemented, reducing the risk of costly remediation work Down the line.

https://www.youtube.com/watch?v=dWJHtk_Px68Another key benefit of the Odex 90 Eccentric Reamer Casing System is its versatility. This system can be used in a wide range of drilling applications, including vertical, horizontal, and directional drilling. Whether you are drilling in soft soil, hard rock, or anything in between, the Odex 90 system can help you achieve optimal results.

Furthermore, the Odex 90 Eccentric Reamer Casing System is designed for ease of use. The system is simple to set up and operate, making it ideal for both experienced drillers and those new to casing drilling. With minimal training required, operators can quickly become proficient in using the Odex 90 system, helping to improve efficiency and productivity on the job site.

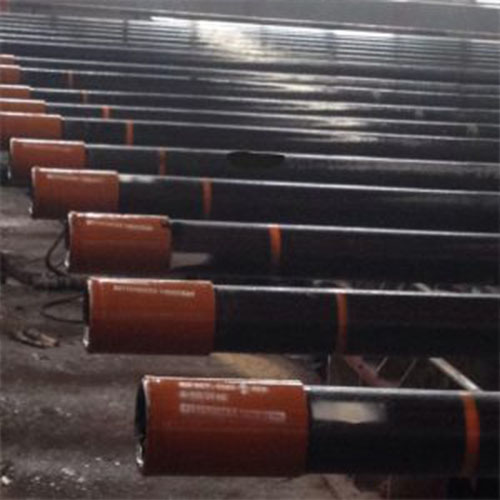

Additionally, the Odex 90 Eccentric Reamer Casing System is built to last. Constructed from high-quality materials and engineered to withstand the rigors of drilling operations, this system is designed for durability and longevity. With proper maintenance and care, the Odex 90 system can provide years of reliable service, helping to maximize your investment in drilling equipment.

In conclusion, the Odex 90 Eccentric Reamer Casing System offers a wide range of benefits that make it a valuable tool for casing drilling operations. From reducing drilling time and improving hole stability to offering versatility, ease of use, and durability, this system has much to offer to drillers looking to streamline their operations and achieve optimal results. If you are in the market for a casing drilling system that delivers on performance and reliability, the Odex 90 system is definitely worth considering.

Step-by-Step Guide on How to Properly Use Odex 90 Eccentric Reamer Casing System

The Odex 90 Eccentric Reamer Casing System is a powerful tool used in the drilling industry to create boreholes for various purposes. This system is designed to efficiently drill through hard rock formations and provide a stable casing for the borehole. Proper usage of the Odex 90 system is crucial to ensure successful drilling operations and minimize the risk of equipment damage or accidents.

To properly use the Odex 90 Eccentric Reamer Casing System, it is important to follow a step-by-step guide that outlines the correct procedures and best practices. This guide will help operators understand how to set up and operate the system effectively, ensuring optimal performance and Safety during drilling operations.

The first step in using the Odex 90 system is to select the appropriate casing size and type for the drilling project. The casing should be compatible with the system and capable of withstanding the drilling conditions. Once the casing is selected, it should be prepared and assembled according to the manufacturer’s instructions.

Next, the Odex 90 system should be properly installed on the drilling rig. This involves attaching the reamer bit to the casing shoe and securing it in place. The system should be checked for any defects or damage before use to prevent malfunctions during drilling.

Before starting the drilling operation, it is important to conduct a thorough inspection of the drilling site and surrounding area. This includes checking for any Obstacles or hazards that could interfere with the drilling process. Safety precautions should be taken to protect personnel and equipment during drilling operations.

Once the site is cleared and prepared, the drilling rig should be positioned over the designated drilling location. The Odex 90 system should be lowered into the borehole, and drilling can commence. The system should be operated at the recommended speed and pressure to achieve optimal drilling performance.

During drilling, operators should monitor the system closely for any signs of malfunction or abnormal behavior. Any issues should be addressed immediately to prevent equipment damage or accidents. Regular maintenance and inspection of the system are essential to ensure its continued performance and longevity.

As the drilling operation progresses, the Odex 90 system will create a stable casing for the borehole. This casing provides support and protection for the borehole walls, preventing collapse and ensuring the integrity of the drilling operation. Once the desired depth is reached, the casing can be cemented in place to secure the borehole.

After completing the drilling operation, the Odex 90 system should be carefully removed from the borehole and inspected for any damage or wear. Any worn or damaged components should be replaced to maintain the system’s performance and reliability.

In conclusion, the Odex 90 Eccentric Reamer Casing System is a valuable tool for drilling operations in hard rock formations. By following a step-by-step guide on how to properly use the system, operators can ensure safe and efficient drilling operations. Proper setup, operation, and maintenance of the system are essential to achieve optimal performance and minimize the risk of equipment damage or accidents.