Table of Contents

Avantages de l’utilisation des tubes sans soudure en alliage SA179, SA192, API5L X42N, X46N, ASME SA335 dans les applications industrielles

Comparaison des tubes sans soudure en alliage SA179, SA192, API5L X42N, X46N, ASME SA335 avec d’autres types de tubes

Lorsqu’il s’agit de choisir le bon type de tube sans soudure pour vos applications industrielles ou commerciales, il est important de prendre en compte les exigences spécifiques de votre projet. Il existe plusieurs types de tubes sans soudure disponibles sur le marché, chacun ayant ses propres propriétés et caractéristiques. Dans cet article, nous comparerons les tubes sans soudure en alliage SA179, SA192, API5L X42N, X46N et ASME SA335 avec d’autres types de tubes pour vous aider à prendre une décision éclairée.

Lorsque vous comparez les tubes sans soudure en alliage SA179, SA192, API5L X42N, X46N et ASME SA335 avec d’autres types de tubes, il est important de prendre en compte les exigences spécifiques de votre projet. Par exemple, si vous avez besoin d’un tube capable de résister à des températures et des pressions élevées, les tubes sans soudure en alliage ASME SA335 peuvent être le meilleur choix pour votre application. En revanche, si vous avez besoin d’un tube très résistant à la corrosion, les tubes sans soudure SA179 ou SA192 peuvent être plus adaptés à vos besoins.

En conclusion, il existe plusieurs types de tubes sans soudure disponibles sur le marché, chacun avec ses propres propriétés et caractéristiques uniques. En comparant les tubes sans soudure en alliage SA179, SA192, API5L X42N, X46N et ASME SA335 avec d’autres types de tubes, vous pouvez prendre une décision éclairée quant au type de tube le mieux adapté à votre application spécifique. Que vous ayez besoin d’un tube pour des échangeurs de chaleur, des chaudières, des pipelines ou des applications à haute température, il existe un tube sans soudure disponible pour répondre à vos besoins.

When it comes to choosing the right type of seamless tube for your industrial or commercial applications, it’s important to consider the specific requirements of your project. There are several different types of seamless tubes available on the market, each with its own unique properties and characteristics. In this article, we will compare SA179, SA192, API5L X42N, X46N, and ASME SA335 alloy seamless tubes with other types of tubes to help you make an informed decision.

SA179 seamless tubes are low Carbon Steel tubes that are widely used in Heat Exchangers, condensers, and other similar applications. These tubes are known for their excellent thermal conductivity and are able to withstand high temperatures and pressures. SA179 tubes are also highly resistant to corrosion, making them a popular choice for a wide range of industrial applications.

SA192 seamless tubes are similar to SA179 tubes in terms of their composition and properties. However, SA192 tubes are specifically designed for high-pressure applications, such as Boilers and superheaters. These tubes are able to withstand extreme temperatures and pressures, making them ideal for use in demanding industrial environments.

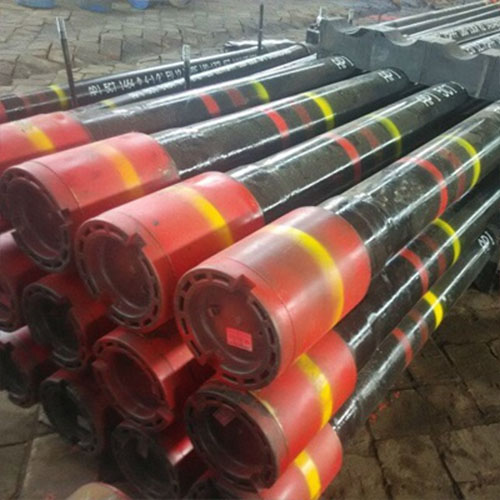

API5L X42N and X46N seamless tubes are commonly used in the oil and gas industry for Transporting Natural Gas and petroleum products. These tubes are made from high-strength carbon steel and are able to withstand the harsh conditions of the oil and gas industry. API5L X42N and X46N tubes are known for their excellent tensile strength and impact resistance, making them a reliable choice for pipeline applications.

ASME SA335 alloy seamless tubes are made from a variety of alloy steels, such as chrome-moly and Nickel alloys. These tubes are specifically designed for high-temperature applications, such as power plants and chemical processing plants. ASME SA335 tubes are able to withstand extreme temperatures and pressures, making them a popular choice for a wide range of industrial applications.

https://www.youtube.com/watch?v=Rw995XQONqsWhen comparing SA179, SA192, API5L X42N, X46N, and ASME SA335 alloy seamless tubes with other types of tubes, it’s important to consider the specific requirements of your project. For example, if you need a tube that can withstand high temperatures and pressures, ASME SA335 alloy seamless tubes may be the best choice for your application. On the other hand, if you need a tube that is highly resistant to corrosion, SA179 or SA192 seamless tubes may be more suitable for your needs.

In conclusion, there are several different types of seamless tubes available on the market, each with its own unique properties and characteristics. By comparing SA179, SA192, API5L X42N, X46N, and ASME SA335 alloy seamless tubes with other types of tubes, you can make an informed decision about which type of tube is best suited for your specific application. Whether you need a tube for heat exchangers, boilers, pipelines, or high-temperature applications, there is a seamless tube available to meet your needs.