Table of Contents

Benefits of Using PET Fibers in Highway Asphalt Mixtures

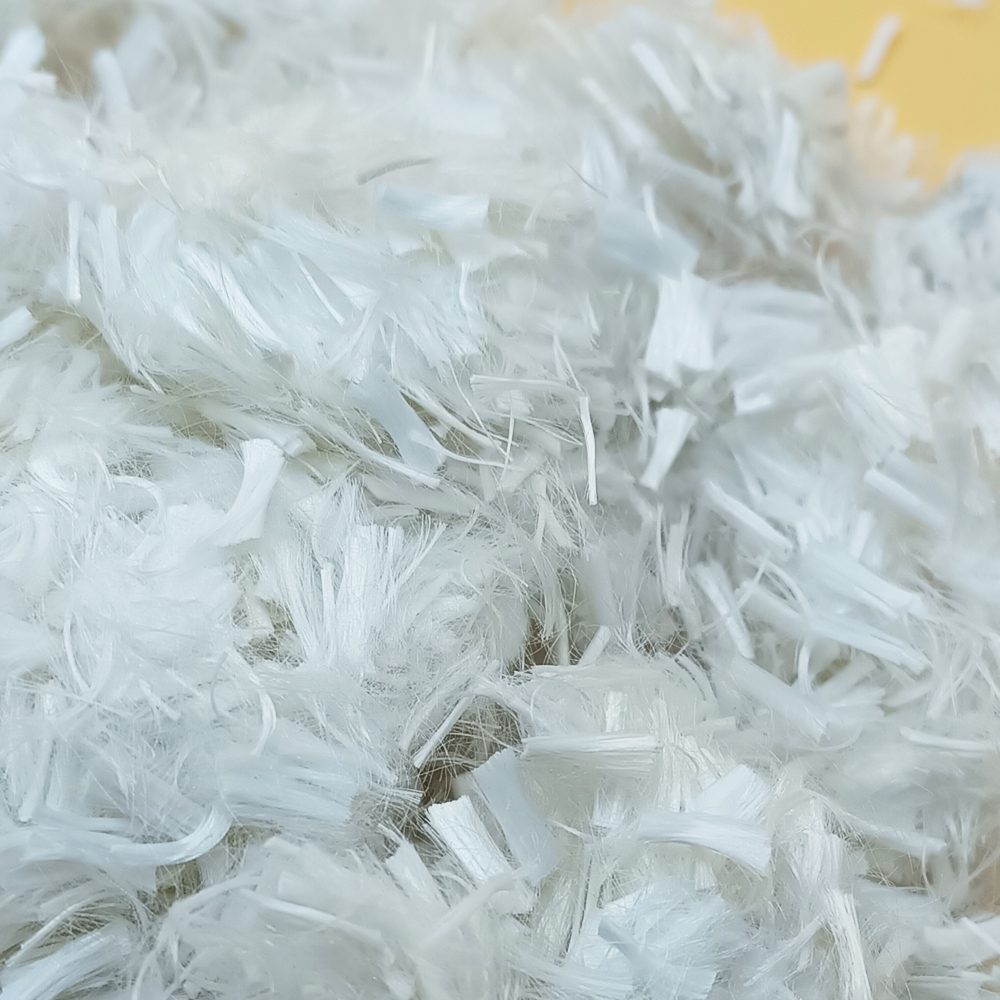

Polyethylene terephthalate (PET) fibers are becoming increasingly popular in the construction industry, particularly in the production of highway asphalt mixtures. These fibers, which are derived from Recycled Plastic bottles, offer a range of benefits that make them an attractive choice for use in road construction projects.

One of the key advantages of using PET fibers in highway asphalt mixtures is their ability to improve the overall performance and durability of the pavement. When added to the asphalt mix, these fibers help to enhance the tensile strength and flexibility of the pavement, making it more resistant to cracking and rutting. This, in turn, can extend the lifespan of the road surface and reduce the need for costly repairs and maintenance in the future.

In addition to improving the structural integrity of the pavement, PET fibers also help to enhance its resistance to moisture and environmental factors. By forming a network of fibers within the asphalt mix, they create a barrier that helps to prevent water from seeping into the pavement and causing damage. This can be particularly beneficial in regions with harsh weather conditions, where moisture infiltration can Lead to premature deterioration of the road surface.

Furthermore, PET fibers can also help to reduce the occurrence of reflective cracking in asphalt pavements. These types of cracks, which often develop over time due to the movement of the underlying layers, can compromise the integrity of the pavement and create Safety hazards for motorists. By reinforcing the asphalt mix with PET fibers, engineers can minimize the risk of reflective cracking and ensure a smoother, more durable road surface.

Another advantage of using PET fibers in highway asphalt mixtures is their environmental sustainability. As a recycled material, PET fibers help to reduce the demand for virgin resources and minimize the amount of plastic waste that ends up in landfills. By incorporating these fibers into road construction projects, engineers can contribute to a more sustainable and eco-friendly infrastructure that benefits both the Environment and the community.

Moreover, PET fibers are easy to handle and mix into asphalt, making them a cost-effective solution for road construction projects. Their lightweight and flexible nature allow for seamless integration into the asphalt mix, without the need for specialized equipment or additional processing. This can help to streamline the construction process and reduce labor costs, making PET fibers a practical choice for highway projects of all sizes.

| Number | Product Name |

| 1 | Polyester Fiber for pavement for Roadway |

In conclusion, the benefits of using PET fibers in highway asphalt mixtures are clear. From improving the structural integrity and durability of the pavement to enhancing its resistance to moisture and environmental factors, these fibers offer a range of advantages that make them an ideal choice for road construction projects. By incorporating PET fibers into asphalt mixtures, engineers can create stronger, more sustainable road surfaces that provide long-lasting performance and safety for motorists.