Table of Contents

Benefits of Using a Hardness Tester for Tablet Quality Control in Chinese Manufacturing

In the world of pharmaceutical manufacturing, ensuring the quality and consistency of tablets is of utmost importance. One key aspect of this quality control process is the measurement of tablet hardness. Tablet hardness refers to the ability of a tablet to withstand mechanical stress or pressure without breaking. This parameter is crucial in determining the tablet’s ability to withstand handling, packaging, and transportation without losing its integrity.

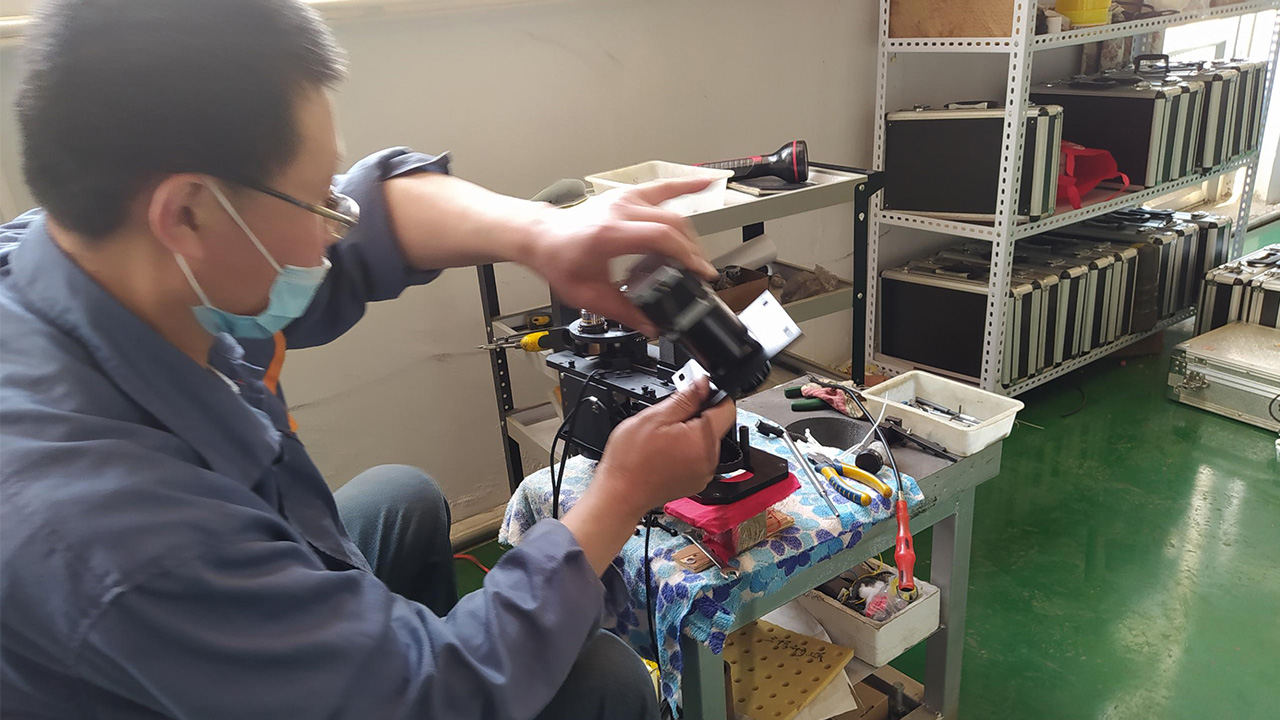

One of the most effective tools for measuring tablet hardness is a hardness tester. A hardness tester is a device specifically designed to measure the resistance of a tablet to compression. By applying a controlled amount of force to the tablet, the hardness tester can accurately determine the tablet’s hardness value. This information is essential for manufacturers to ensure that their tablets meet the required quality standards.

In Chinese manufacturing, the use of hardness testers has become increasingly popular due to their accuracy and reliability. Chinese manufacturers are known for their high-quality products at competitive prices, and hardness testers are no exception. Chinese manufacturers have invested heavily in research and development to produce high-grade hardness testers that meet international standards.

One of the key benefits of using a hardness tester for tablet quality control in Chinese manufacturing is the assurance of consistent tablet quality. By measuring the hardness of each tablet, manufacturers can identify any variations in hardness values and take corrective actions to ensure uniformity across all tablets. This level of quality control is essential for meeting regulatory requirements and maintaining customer satisfaction.

Another benefit of using a hardness tester in Chinese manufacturing is the cost-effectiveness of these devices. Chinese manufacturers are able to produce high-grade hardness testers at a fraction of the cost of their Western counterparts. This cost advantage allows Chinese manufacturers to invest in state-of-the-art hardness Testing Equipment without compromising on quality.

Furthermore, Chinese manufacturers are known for their efficiency and speed in production. By using hardness testers to quickly and accurately measure tablet hardness, manufacturers can streamline their quality control processes and reduce the time and resources required for testing. This efficiency not only improves productivity but also allows manufacturers to deliver high-quality tablets to market faster.

In addition to consistency, cost-effectiveness, and efficiency, Chinese manufacturers also benefit from the versatility of hardness testers. These devices can be used to measure the hardness of a wide range of tablet formulations, including immediate-release, extended-release, and chewable tablets. This versatility allows manufacturers to adapt their quality control processes to meet the specific requirements of each tablet formulation.

Overall, the use of a hardness tester for tablet quality control in Chinese manufacturing offers numerous benefits, including consistent tablet quality, cost-effectiveness, efficiency, and versatility. Chinese manufacturers have recognized the importance of accurate hardness testing in ensuring the quality and integrity of their tablets. By investing in high-grade hardness testers, Chinese manufacturers can continue to produce high-quality tablets at competitive prices while meeting international quality standards.