Table of Contents

Copper Customizable Wire: Tips and Tricks for Crafting Unique Designs

Copper customizable wire is a versatile material that can be used for a wide range of crafting projects. Whether you are a beginner or an experienced crafter, there are many tips and tricks that can help you create unique designs with copper wire.

One of the key advantages of copper wire is its flexibility. This allows you to easily bend and shape the wire into intricate designs. To make the most of this flexibility, it is important to use the right tools. A pair of round-nose pliers can help you create smooth curves and loops, while flat-nose pliers are ideal for making sharp bends and angles.

When working with copper wire, it is important to consider the thickness of the wire. Thicker wire is more durable and can hold its shape better, making it ideal for larger projects. However, thinner wire is more flexible and can be easier to manipulate for intricate designs. Experimenting with different thicknesses of wire can help you find the right balance for your project.

Another important factor to consider when working with copper wire is the finish. Copper wire is available in a variety of finishes, including shiny, matte, and oxidized. The finish you choose can have a big impact on the final look of your project. Shiny copper wire can add a touch of elegance, while oxidized copper wire can create a more rustic or vintage look.

In addition to its flexibility and finish, copper wire is also easy to customize. You can easily add beads, charms, or other embellishments to your wire designs to create a unique look. Experimenting with different combinations of wire and beads can help you create one-of-a-kind pieces that reflect your personal style.

Stainless Steel wire egg baskets are another popular crafting material that can be used to create unique designs. Like copper wire, stainless steel wire is flexible and durable, making it ideal for a wide range of projects. Stainless steel wire is also resistant to rust and corrosion, making it a great choice for outdoor projects or items that will be exposed to moisture.

When working with stainless steel wire, it is important to use the right tools. Stainless steel wire is harder than copper wire, so you may need to use stronger pliers or wire cutters to manipulate it. Additionally, stainless steel wire can be more difficult to bend and shape, so it is important to take your time and work carefully to avoid damaging the wire.

Like copper wire, stainless steel wire is available in a variety of finishes. Stainless steel wire can be polished to a shiny finish, or left unpolished for a more industrial look. Experimenting with different finishes can help you create unique designs that stand out.

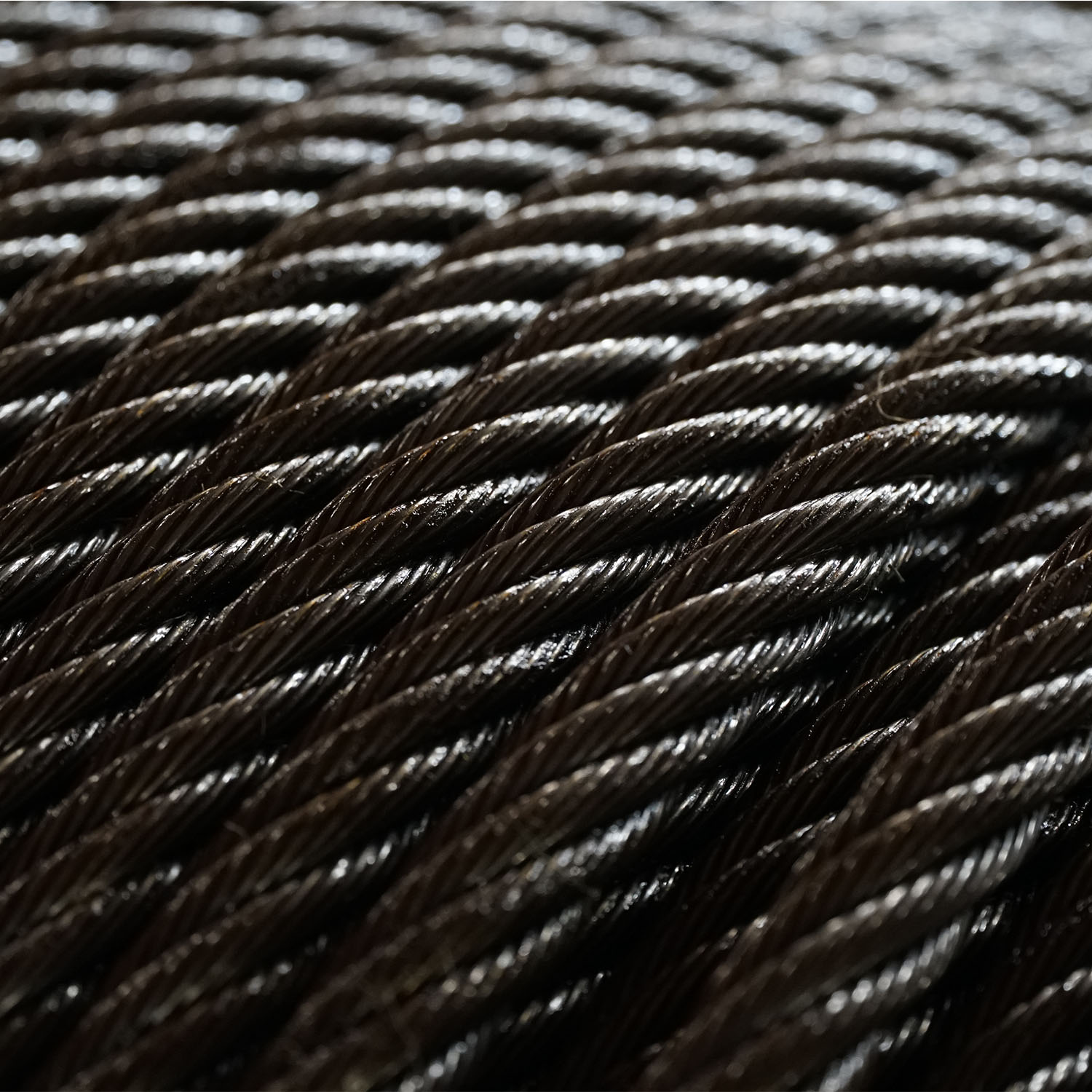

An insight into wire Rope geometry can help you understand the structure and properties of wire ropes. Wire ropes are made up of multiple strands of wire twisted together to form a strong and flexible cable. The geometry of a wire rope, including the number of strands, the direction of twist, and the lay length, can have a big impact on its strength and performance.

The number of strands in a wire rope can vary, with more strands generally resulting in a stronger rope. The direction of twist refers to the way the individual strands are twisted together, with right-hand and left-hand twists being the most common. The lay length refers to the distance it takes for a strand to make one complete revolution around the rope.

Understanding the geometry of wire ropes can help you choose the right rope for your project. For example, a wire rope with a higher number of strands and a longer lay length will be stronger and more flexible, making it ideal for heavy-duty applications. On the other hand, a wire rope with a lower number of strands and a shorter lay length may be more rigid and less flexible, making it better suited for lighter-duty applications.

In conclusion, copper customizable wire, stainless steel wire egg baskets, and wire rope geometry are all important aspects of crafting that can help you create unique designs. By understanding the properties and characteristics of these materials, you can create one-of-a-kind pieces that reflect your personal style and creativity. Experimenting with different techniques and materials can help you push the boundaries of your crafting skills and create truly unique and beautiful pieces.

Stainless Steel Wire Egg Basket: A Stylish and Functional Addition to Your Kitchen

Copper customizable wire and stainless steel wire egg baskets are not only stylish additions to your kitchen, but they also serve a functional purpose. These baskets are designed to hold and store Eggs, keeping them safe and secure while adding a touch of elegance to your kitchen decor.

Copper customizable wire egg baskets are a popular choice for many homeowners due to their versatility and customizable options. These baskets can be made to fit any size or shape, making them perfect for storing a dozen eggs or just a few. The copper material adds a touch of warmth and sophistication to your kitchen, while the wire design allows for easy visibility of the eggs inside.

Stainless steel wire egg baskets, on the other hand, offer a more modern and sleek look to your kitchen. The durable stainless steel material is easy to clean and maintain, making it a practical choice for everyday use. The wire design of these baskets allows for air circulation around the eggs, helping to keep them fresh for longer periods of time.

When it comes to wire rope geometry, there are a few key factors to consider. The diameter of the wire rope plays a crucial role in its strength and durability. Thicker ropes are able to withstand heavier loads, making them ideal for applications where strength is a priority. The construction of the wire rope, whether it is made of individual wires twisted together or a single strand of wire, also affects its overall strength and flexibility.

The lay of the wire rope refers to the direction in which the wires are twisted together. A regular lay rope has wires that are twisted in the same direction as the rope itself, while a lang lay rope has wires that are twisted in the opposite direction. The lay of the wire rope can affect its flexibility and resistance to abrasion, so it is important to choose the right type of lay for your specific application.

In addition to diameter, construction, and lay, the core of the wire rope is another important factor to consider. The core provides support and stability to the rope, helping to maintain its shape and strength under heavy loads. There are several types of cores available, including Fiber cores, independent wire rope cores, and steel cores, each offering different Levels of strength and flexibility.

Overall, copper customizable wire and stainless steel wire egg baskets are stylish and functional additions to any kitchen. Their unique designs and materials make them a practical choice for storing and displaying eggs, while wire rope geometry plays a crucial role in the strength and durability of various applications. By understanding the key factors that affect wire rope performance, you can choose the right type of wire rope for your specific needs and ensure that it will perform reliably for years to come.

An Insight into Wire Rope Geometry: Understanding the Mechanics Behind Strong and Durable Structures

Wire rope is a crucial component in many industries, providing strength and durability in a variety of applications. Understanding the geometry of wire rope is essential for ensuring its performance and longevity. In this article, we will delve into the intricacies of wire rope geometry, focusing on copper customizable wire and stainless steel wire egg baskets.

Wire rope is composed of individual wires twisted together to form strands, which are then twisted together to create the final rope. The geometry of wire rope plays a significant role in its strength and flexibility. The number of wires in each strand, the direction of the twist, and the lay length all impact the performance of the rope.

Copper customizable wire is a popular choice for applications that require high electrical conductivity and corrosion resistance. The geometry of copper wire rope is carefully engineered to maximize these properties. By increasing the number of wires in each strand, manufacturers can enhance the conductivity of the rope. Additionally, a tighter lay length can improve the flexibility of the rope, making it easier to handle and install.

Stainless steel wire egg baskets are another example of wire rope geometry at work. These baskets are used in a variety of industries, including Agriculture and food processing. The geometry of stainless steel wire rope is designed to provide strength and durability in harsh environments. By using a higher grade of stainless steel and a larger diameter wire, manufacturers can create a basket that can withstand heavy loads and resist corrosion.

One of the key factors in wire rope geometry is the lay length, which refers to the distance it takes for a wire to make a complete revolution around the rope. A shorter lay length results in a more flexible rope, while a longer lay length provides greater strength. By adjusting the lay length, manufacturers can tailor the performance of the rope to meet specific requirements.

The direction of the twist is another important aspect of wire rope geometry. Most wire ropes are constructed with a right-hand lay, meaning that the strands and wires are twisted in a clockwise direction. This configuration provides optimal strength and stability. However, in some applications, a left-hand lay may be used to counteract the effects of torque or vibration.

In conclusion, understanding the geometry of wire rope is essential for ensuring the performance and longevity of these critical components. Whether it’s copper customizable wire for electrical applications or stainless steel wire egg baskets for industrial use, the careful engineering of wire rope geometry plays a crucial role in creating strong and durable structures. By considering factors such as the number of wires, lay length, and twist direction, manufacturers can tailor wire rope to meet the specific needs of each application.