Table of Contents

Importance of Carbon Content in Steel Wire Rope

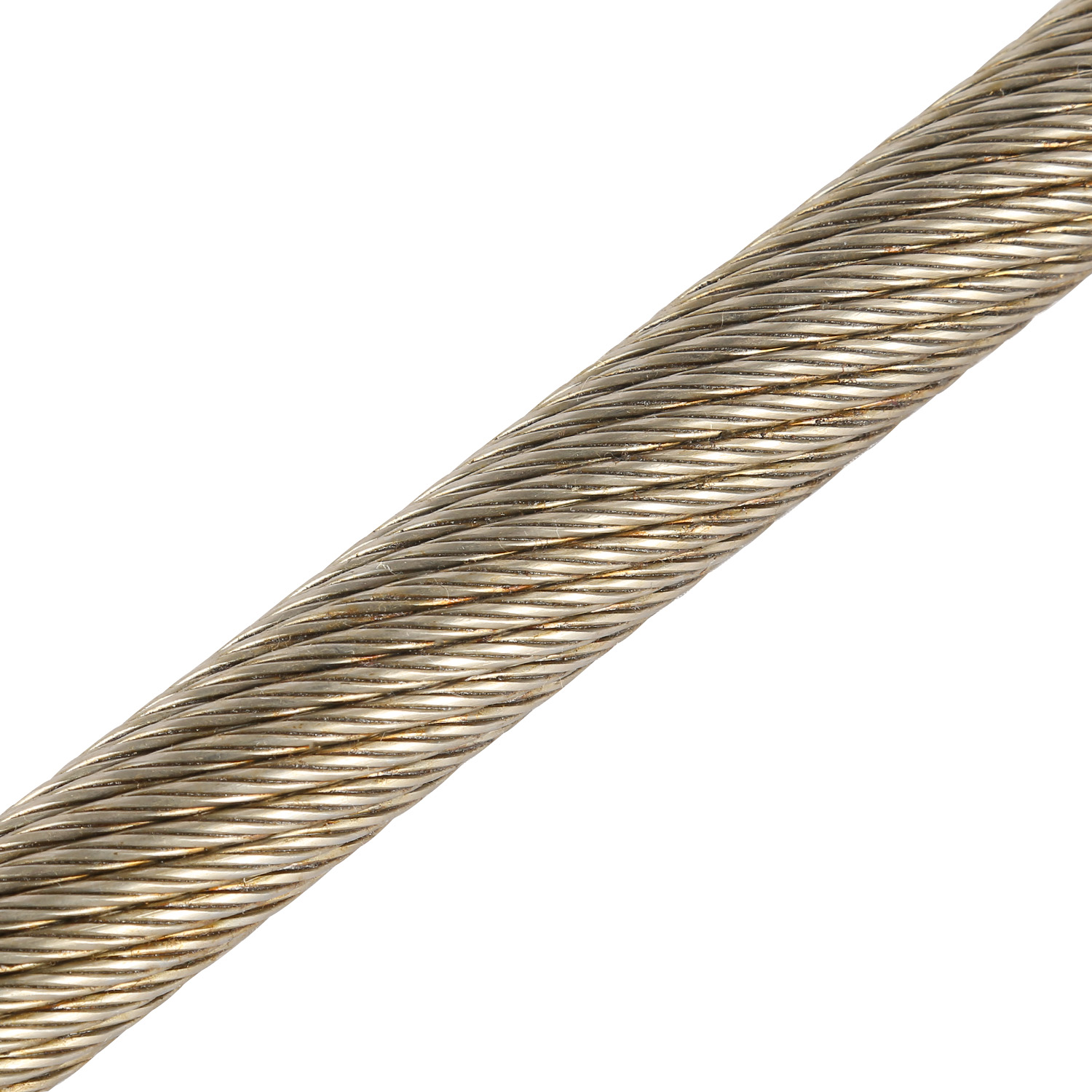

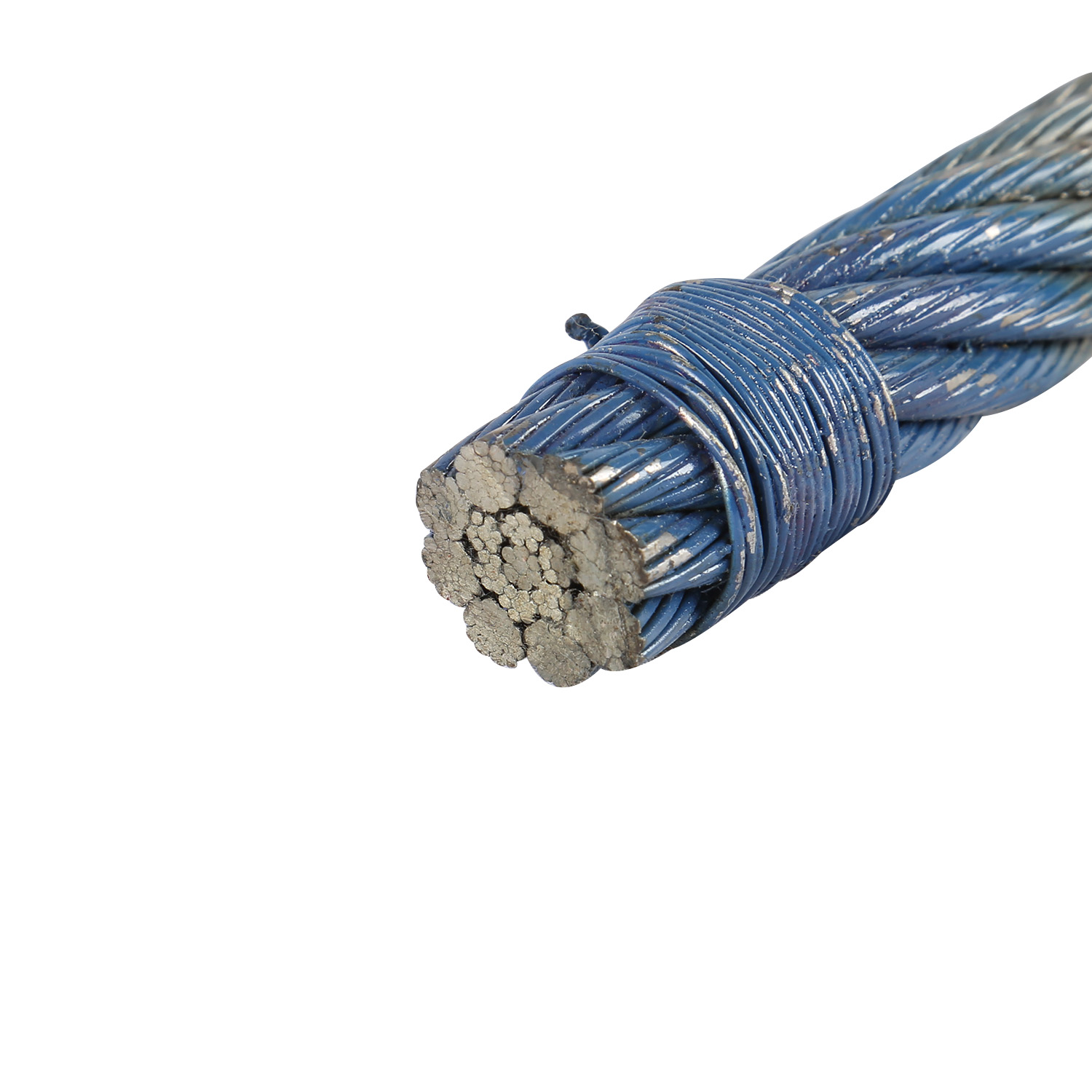

Steel wire rope is a crucial component in various industries, including construction, mining, and transportation. Its strength and durability make it an essential material for lifting heavy loads and providing support in various applications. The chemical composition of steel wire rope plays a significant role in determining its mechanical properties, including strength, flexibility, and resistance to corrosion.

One of the most critical elements in the chemical composition of steel wire rope is carbon. Carbon is a key alloying element that influences the strength and hardness of steel. The amount of carbon present in the steel affects its ability to withstand tensile forces and resist deformation under load. Higher carbon content generally results in higher strength and hardness, making the steel more suitable for heavy-duty applications.

The carbon content in steel wire rope is typically controlled within a specific range to achieve the desired mechanical properties. Low-Carbon Steel wire rope contains less than 0.3% carbon and is known for its flexibility and ease of bending. This type of steel wire rope is commonly used in applications where flexibility is essential, such as in crane cables and Elevator ropes.

On the other hand, high-carbon steel wire rope contains more than 0.6% carbon and is characterized by its high strength and hardness. This type of steel wire rope is ideal for applications that require superior strength and resistance to wear, such as in mining and heavy construction. The high carbon content allows the steel wire rope to withstand heavy loads and abrasive environments without deforming or breaking.

The carbon content in steel wire rope can also affect its resistance to corrosion. Carbon steel wire rope is susceptible to rust and corrosion when exposed to moisture and harsh environmental conditions. To improve the corrosion resistance of carbon steel wire rope, manufacturers often apply a protective coating or galvanize the rope to create a barrier against moisture and corrosive agents.

In addition to carbon, other alloying elements such as manganese, silicon, and chromium can also influence the mechanical properties of steel wire rope. Manganese is commonly added to steel to improve its strength and toughness, while silicon helps enhance the steel’s resistance to oxidation and scaling at high temperatures. Chromium is often used to increase the steel’s corrosion resistance and durability.

The proper balance of alloying elements in the chemical composition of steel wire rope is essential to ensure that it meets the specific requirements of the application. By carefully controlling the carbon content and other alloying elements, manufacturers can produce steel wire rope with the desired combination of strength, flexibility, and corrosion resistance.

In conclusion, the chemical composition of steel wire rope, particularly the carbon content, plays a crucial role in determining its mechanical properties and performance in various applications. Whether low-carbon or high-carbon steel wire rope is required, the right balance of alloying elements is essential to ensure that the rope meets the specific requirements of the application. By understanding the importance of carbon content in steel wire rope, manufacturers can produce high-quality products that meet the demands of modern industries.

Effects of Alloying Elements on Steel Wire Rope Properties

Steel wire rope is a crucial component in various industries, including construction, mining, and transportation. Its strength and durability make it an ideal choice for lifting heavy loads and providing support in various applications. The chemical composition of steel wire rope plays a significant role in determining its properties, such as strength, flexibility, and corrosion resistance.

Alloying elements are added to steel to enhance its properties and improve its performance in specific applications. These elements can alter the microstructure of the steel, resulting in changes in its mechanical properties. Some common alloying elements used in steel wire rope include carbon, manganese, silicon, Nickel, chromium, and Molybdenum.

Carbon is one of the most important alloying elements in steel wire rope. It is added to improve the strength and hardness of the steel. Higher carbon content increases the tensile strength of the steel, making it suitable for applications that require high strength and durability. However, excessive carbon content can also reduce the ductility and toughness of the steel, making it more prone to cracking and failure.

Manganese is another essential alloying element in steel wire rope. It is added to improve the hardenability of the steel and enhance its strength and toughness. Manganese also helps in deoxidizing the steel and improving its weldability. Silicon is often added to steel to improve its resistance to corrosion and oxidation. It also helps in deoxidizing the steel and improving its strength and toughness.

Nickel is a common alloying element used in steel wire rope to improve its corrosion resistance and toughness. Nickel also enhances the ductility and weldability of the steel, making it suitable for applications that require high strength and durability. Chromium is another important alloying element in steel wire rope. It is added to improve the steel’s resistance to corrosion and oxidation. Chromium also enhances the hardenability of the steel and improves its strength and toughness.

Molybdenum is often added to steel wire rope to improve its strength, toughness, and corrosion resistance. Molybdenum also helps in enhancing the hardenability of the steel and improving its weldability. Other alloying elements, such as vanadium, Titanium, and Copper, are also used in steel wire rope to enhance its properties and improve its performance in specific applications.

The chemical composition of steel wire rope plays a crucial role in determining its properties and performance. Alloying elements are added to steel to enhance its strength, toughness, and corrosion resistance. Each alloying element has a specific role in improving the properties of the steel and making it suitable for various applications.

In conclusion, the chemical composition of steel wire rope is essential in determining its properties and performance. Alloying elements are added to steel to enhance its strength, toughness, and corrosion resistance. Understanding the effects of alloying elements on steel wire rope properties is crucial in selecting the right material for specific applications. By carefully selecting the appropriate alloying elements, manufacturers can produce steel wire rope with the desired properties and performance characteristics.

Corrosion Resistance of Stainless Steel Wire Rope

Steel wire rope is a versatile and durable material used in a wide range of applications, from construction and mining to marine and aerospace industries. One of the key factors that determine the performance and longevity of steel wire rope is its chemical composition. In this article, we will delve into the chemical composition of steel wire rope, with a focus on its corrosion resistance.

Steel wire rope is typically made from high-strength carbon steel, which is alloyed with other elements to enhance its mechanical properties. The most common alloying elements used in steel wire rope are chromium, nickel, and molybdenum. These elements play a crucial role in improving the corrosion resistance of the steel wire rope, making it suitable for use in harsh environments where exposure to moisture, Chemicals, and other corrosive agents is a concern.

Chromium is one of the most important alloying elements in stainless steel wire rope. It forms a passive Oxide layer on the surface of the steel, which acts as a barrier to prevent corrosion from penetrating into the material. The higher the chromium content in the steel wire rope, the better its corrosion resistance. Stainless steel wire rope typically contains at least 10.5% chromium, although higher chromium content grades such as 316 and 316L are also commonly used for applications requiring superior corrosion resistance.

Nickel is another key alloying element in stainless steel wire rope. It helps to improve the ductility and toughness of the material, making it more resistant to cracking and deformation under high loads. Nickel also enhances the corrosion resistance of stainless steel wire rope by stabilizing the austenitic structure of the material, which is more resistant to corrosion than other crystal structures. Stainless steel wire rope with higher nickel content, such as grade 316, is often used in marine and offshore applications where exposure to saltwater and harsh weather conditions is a concern.

Molybdenum is a less common alloying element in stainless steel wire rope, but it plays a crucial role in enhancing the material’s resistance to pitting and crevice corrosion. Pitting corrosion occurs when small pits or holes form on the surface of the material, while crevice corrosion occurs in confined spaces where oxygen Levels are low. Stainless steel wire rope with molybdenum content, such as grade 316, is highly resistant to both types of corrosion, making it ideal for use in aggressive environments where corrosion is a major concern.

In addition to chromium, nickel, and molybdenum, stainless steel wire rope may also contain other alloying elements such as copper, titanium, and nitrogen, depending on the specific grade and application requirements. These elements can further enhance the mechanical properties and corrosion resistance of the material, making it suitable for a wide range of demanding applications.

In conclusion, the chemical composition of steel wire rope plays a crucial role in determining its corrosion resistance and overall performance. By alloying the material with elements such as chromium, nickel, and molybdenum, stainless steel wire rope can be tailored to meet the specific requirements of different applications, from marine and offshore to construction and mining. Understanding the chemical composition of steel wire rope is essential for selecting the right grade and ensuring the long-term durability and reliability of the material in corrosive environments.