Table of Contents

Benefits of Using 4.5 Inch Oil Well Casing in Oil Drilling Operations

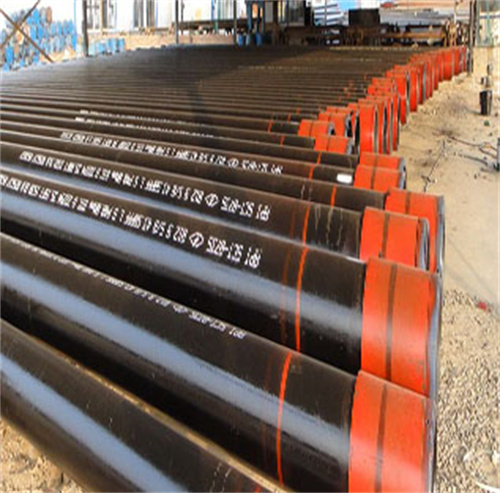

Oil drilling operations are a crucial part of the global energy industry, providing the necessary resources to power our daily lives. One essential component of oil drilling operations is the use of oil well casing, which plays a vital role in ensuring the success and efficiency of the drilling process. In this article, we will explore the benefits of using 4.5 inch oil well casing in oil drilling operations and why it is preferred by many oil drilling companies.

One of the primary benefits of using 4.5 inch oil well casing is its durability and strength. Oil drilling operations can be extremely demanding and require equipment that can withstand high Levels of pressure and stress. The 4.5 inch oil well casing is made from high-quality materials that are designed to withstand the harsh conditions of oil drilling, making it a reliable and long-lasting option for oil drilling companies.

In addition to its durability, the 4.5 inch oil well casing also offers excellent corrosion resistance. The casing is exposed to various corrosive elements during the drilling process, such as saltwater and Chemicals, which can cause damage and reduce the lifespan of the casing. However, the 4.5 inch oil well casing is specially treated to resist corrosion, ensuring that it remains in optimal condition for an extended period of time.

Furthermore, the 4.5 inch oil well casing is designed to provide a tight seal, preventing any leaks or seepage of oil or other fluids during the drilling process. This is essential for maintaining the integrity of the well and ensuring that the drilling operation is safe and efficient. The tight seal also helps to prevent contamination of the surrounding Environment, protecting the ecosystem and minimizing the impact of the drilling operation.

Another benefit of using 4.5 inch oil well casing is its versatility and compatibility with various drilling equipment and techniques. The casing can be easily installed and connected to other components of the drilling operation, allowing for seamless integration and efficient operation. This versatility makes the 4.5 inch oil well casing a popular choice among oil drilling companies, as it can be used in a wide range of drilling applications.

In conclusion, the benefits of using 4.5 inch oil well casing in oil drilling operations are numerous and significant. From its durability and corrosion resistance to its tight seal and versatility, the 4.5 inch oil well casing offers a range of advantages that make it an ideal choice for oil drilling companies. By investing in high-quality oil well casing, companies can ensure the success and efficiency of their drilling operations, ultimately leading to increased productivity and profitability.

How to Choose the Right Oil Casing Pipe Supplier for Your Crude Ape Tube Needs

When it comes to oil drilling, having the right equipment is crucial for the success of the operation. One of the key components in oil drilling is the oil casing pipe, which plays a vital role in protecting the wellbore and ensuring the integrity of the well. With so many suppliers offering oil casing pipes in the market, it can be overwhelming to choose the right one for your crude ape tube needs. In this article, we will discuss some important factors to consider when selecting an oil casing pipe supplier.

First and foremost, it is essential to consider the quality of the oil casing pipes offered by the supplier. The quality of the casing pipe will directly impact the performance and longevity of the well. Look for suppliers who provide high-quality oil casing pipes that meet industry standards and regulations. It is also important to inquire about the manufacturing process and materials used in the production of the casing pipes to ensure their durability and reliability.

In addition to quality, it is crucial to consider the reputation and experience of the oil casing pipe supplier. A supplier with a good reputation in the industry is more likely to provide reliable products and excellent customer service. Look for suppliers who have a proven track record of delivering high-quality oil casing pipes to their customers. You can also check online reviews and testimonials from previous clients to gauge the supplier’s reputation and reliability.

Another important factor to consider when choosing an oil casing pipe supplier is the range of products and services offered. A reputable supplier should offer a wide selection of oil casing pipes in various sizes, grades, and specifications to meet the specific needs of your crude ape tube. Additionally, look for suppliers who provide additional services such as customization, testing, and inspection to ensure the quality and performance of the casing pipes.

Furthermore, it is essential to consider the pricing and delivery options offered by the oil casing pipe supplier. Compare prices from different suppliers to ensure that you are getting the best value for your money. Additionally, inquire about the delivery options and Lead times to ensure that the casing pipes will be delivered on time to meet your drilling schedule.

Lastly, it is important to consider the customer support and after-sales service provided by the oil casing pipe supplier. A reliable supplier should offer excellent customer support to address any concerns or issues that may arise during the drilling process. Look for suppliers who provide technical assistance, maintenance services, and warranty options to ensure the long-term performance of the oil casing pipes.

In conclusion, choosing the right oil casing pipe supplier is essential for the success of your crude ape tube drilling operation. Consider factors such as quality, reputation, range of products, pricing, delivery options, and customer support when selecting a supplier. By taking the time to research and evaluate different suppliers, you can ensure that you are getting high-quality oil casing pipes that meet your specific needs and requirements.